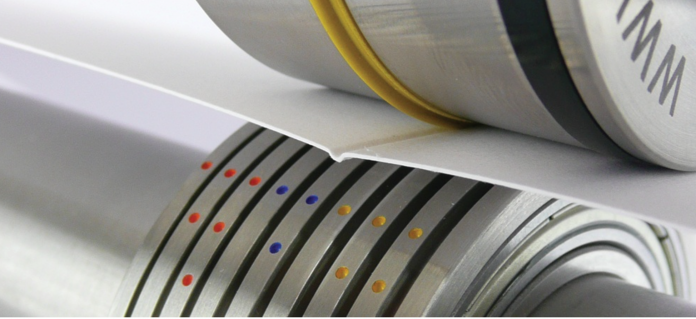

Tech-ni-Fold’s Tri-creaser Fast Fit device fits onto an existing folding machine’s exit shafts and eliminates fibre cracking. This device is simple to use, and even an unskilled person will be able to produce cylinder quality creasing within minutes and also have the benefit of folding the work at the same time.

Users can produce one of eight crease style choices for any stock/print application imaginable and change from one crease setting to another instantly using the simple colour coding system. The clever split creasing ribs provide users with a unique way to attach the correct setting without taking the device off the folding machine’s exit shafts. Applying one of three colour-coded creasing ribs is now so quick it reduces set up times dramatically. The device also provides excellent results, even on digitally printing materials.

Benefits include:

– Completely eliminates fibre cracking 100% on stock ranges 85-350gsm.

– Produces a crease that is as good as or better than a flatbed cylinder impression.

– Takes only minutes to set up and seconds to change from one crease setting to another.

– No waiting for the slow cylinder.

– Saves on expensive transport and outsourcing costs.

– Cuts out a process altogether.

– Users can crease and fold at the same time.

– Works as fast as your folding machine can run.

– No costly specialist machine purchase.

– Allows users to deliver a finished product on time.

Tech-ni-Fold™ Fast-Fit is compatible with the following folding and scoring machines:

– Heidelberg.

– Stahl.

– MBO.

– Horizon.

– Econocrease.

– Rollem.

– Rosback.

– Baumfolder.

ATS – Advanced Technology Solutions (+27 11) 675 6397 nadine.hayns@ats-sa.co.za www.ats-sa.co.za