The TRESU inline CI flexo printing machines reduce brand owners’ time to market and offer an opportunity for frequent design changes in response to seasonal trends or fashion demands.

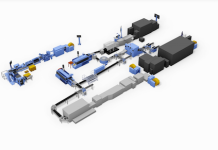

TRESU will present an updated range of modular inline CI flexo printing machines that reduce the cost to print in branded non-woven printing applications. A fully automated single pass converting line with integrated inline printing technology optimises the ability to meet brand owners’ demand for branded non-woven goods, while having the flexibility to also offer competitive shorter production runs and shorter lead-times, with costs firmly controlled.

Inline flexo printing reduces stock complexity, logistics and dependence on pre-printed materials with a fully automated HMI design requiring minimal operator training. A new updated platform enables customers to choose the features they need now and add optional modules of their choice later when need arises.

The TRESU CI flexo printing units comprise up to four water-based colours, a hot air dryer and a register system – all contained within a single module and offering both a compact footprint and a user-friendly design with only a minimum of operator training required.

The compact housings and build-in measures of TRESU’s inline CI flexo printing machines are also ideal for retrofitting, where space is limited, but quality requirements are high. Combining in-house inline printing with an efficient drying technology and water-based ink is a sustainable way of printing non-woven materials. TRESU will present the range at INDEX 2023 in Geneva from April 18-21.

IPEX MACHINERY

+27 11 493 7816

info@ipex.co.za

http://www.ipex.co.za/