With Layout Library, printers teach their MIS how to lay down impositions in the correct way for their equipment and processes. This will remove the need for prepress to manually adjust or change the impositions sent down by the MIS.

Keith McMurtrie, Tharstern’s MD and the driving force behind this milestone development said, ‘MIS-to-prepress connectivity is pivotal to automation and while there have been great strides made in this area, it has still always felt like all of the knowledge was held in prepress and the MIS was only sending a rough idea of the imposition layout for prepress to interpret and make good. On the whole, that did work, but one of the challenges that have remained unconquerable in our opinion is change control. When prepress make changes to an imposition, the integrity of the workflow is broken and feedback about job status and costing is nearly impossible. Some prepress systems have gone a long way in trying to communicate this information back to the MIS but honestly, it’s typically too late or too difficult to flush that information into the relevant areas for each job. There are just too many implications.’

McMurtrie said that after many years of painful workflow deployment experience where they repeatedly had to deal with the unavoidable damage caused by these exceptional situations, they concluded that they would need to fix the problem further upstream, at the MIS level. They would need to find a way to ensure that the imposition sent downstream by the MIS was the correct one.

‘The problem with automatic impositions created by an MIS solution, is that they follow industry standards and best practice, but each and every company we work with has so many variables and personal preferences that affect how they want to lay down their impositions. There isn’t an automatic one-size-fits-all way to do this. What people seem to want in an automatic production route is for the MIS to come up with the layout that they would have selected manually,’ added McMurtrie.

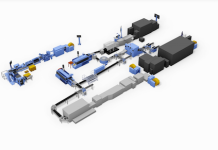

This is fundamentally what Tharstern have achieved with their new Layout Library. While the MIS will still create dynamic impositions automatically, there is now the added functionality to ‘teach’ the software about any exceptions to the rules. Printers can tell their MIS exactly how to lay down different products and different parts and can control all the flipping and rotating of their signatures and sheets to fit in with their equipment and workflow. They can make allowances for non-printable regions for slow-down wheels, flex signature and sheet sizes automatically and also support variable cut-off cut-star type equipment.

These Layout Profiles are then assigned product types and criteria (e.g. substrate, run length, orientation and grain direction) so the estimating engine within Tharstern knows which imposition to select for that product type and situation. The layouts can be associated with different equipment e.g. one imposition for digital and one for litho, one imposition for a booklet maker and one for conventional binding. And users can also set different layouts for situations where the imposition needs to be different because of some other post-press process such as die-cutting.