Tag: bobst

BOBST Alliance Aims To Push Limits Of Hot-Stamping Technology

BOBST and KURZ have announced a strategic partnership to advance hot-transfer technology. The two companies have decided to extend their collaboration by showcasing the...

BOBST Client Invests In Fourth Metalliser

SRF have invested in a fourth BOBST metalliser for their factory in India. The EXPERT K5 3650mm will be up and running next year....

BOBST Customer Achieves Sustainability With Packaging Expansion

Over the past decade, Drorys Packlist S.p.A. has built a solid partnership with BOBST, investing in both gravure and flexo print technology from the...

Label Printer Boosts Production With BOBST Press

Preparing for future challenges and continuing its commitment to sustainability, Italian label printer etic.a has installed a BOBST DIGITAL MASTER 340 All-in-One label press...

BOBST Press Streamlines Production For Label Manufacturer

Based on the experience with its service and support over more than two decades, Autoadesivi Cipriani renewed its faith in BOBST’s inline flexo technology...

BOBST Enhances Folding-Gluing Machine Range

In 2021, BOBST introduced the A3 version of the EXPERTFOLD 50/80/110, a new configuration which cut down changeover time between crash-lock bottom boxes and...

BOBST Packaging Customer Installs Folder-Gluer

Corrugated manufacturer Grigeo Packaging UAB is a subsidiary company of Grigeo Group, one of the largest paper and hardboard manufacturers in the Baltics. The...

Customer Chooses BOBST Metalliser To Meet Increasing Market Demand

PT Argha Karya Prima Industry Tbk, based in Indonesia, purchased a BOBST EXPERT K5 is to further increase capacity due to a growing demand...

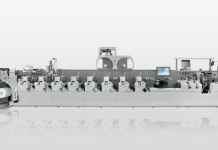

BOBST Announces Customer’s Second Investment In Flexo Press

The 430mm wide BOBST MASTER M5 is configured for 8-colour UV flexo printing. Its PrintTutor system ensures precise and automatic register control, offering the...

BOBST Technology Enables Production Of Complex Packaging

Schumacher Packaging uses the e-commerce version of the BOBST EXPERTFOLD 110 folder-gluer to produce shipping packaging that covers market requirements across Europe. The German...