Manroland sheetfed will use drupa 2012 to communicate its excitement about the start of a new era for the newly structured company and visitors can expect to see a fresh new spirit that reflects both innovation and the continuation of the tradition of excellence associated with the two hundred year old manroland brand.

Visitors to our stand will clearly observe the power of manroland sheetfed solutions to help their companies face the many challenges of today’s printing industry with the most innovative and productive sheetfed offset solutions in the industry, said Alfred Rothlaender, President of manroland sheetfed. With our new structure firmly in place, customers will experience an even more responsive partner in manroland sheetfed. We are dedicated to helping customers future-proof their businesses as we work hard to meet or exceed their expectations for excellence, both in product and services.

Packaging Opportunities

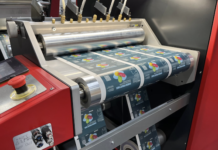

A key element of manroland sheetfed’s drupa presence will be its solutions for the packaging market. These solutions have been created based on intensive research and development as well as customer feedback about market requirements, and include:

– The ROLAND 708LV printing press equipped with the new indexed InlineFoiler, which saves up to 55% in consumption of foil.

– An inline coating unit for added value printing effects that enhance the already high quality delivered by the press.

– Intelligent colour pre-setting with self-learning software that can bring ongoing productivity gains to the production floor.

– All required inline control technology, from colour to register and full sheet inspection down to 200dpi, along with PDF comparison down to 4pt text (multiple camera system) to ensure accuracy and readability of the final printed product.

Visitors to the company’s stand will also be able to learn about other high productivity packaging solutions, like the production in half-format with the ROLAND 500 and medium format with the ROLAND 700 as well as special 0B+ and 3B+ sizes, with speeds as high as 18000 sheets per hour. In addition, manroland sheetfed now offers larger formats 5 and 6 with the ROLAND 900 at speeds of up to 16000 sheets per hour with the high speed packaging equipment. The company also offers logistic solutions, from the new automated non-stop to full configurations that deliver efficient process optimisation individually scalable to every printer’s needs (AUPASYS).

Continued Innovation in Commercial Print

In addition to pursuing advanced solutions for the packaging market, manroland sheetfed also offers innovative solutions for the commercial printing market. This includes the ability for printers to better address customer requirements for faster turnaround using its sheetfed solutions that include:

– The Just-Ready-Print solution powered by LEC-UV.

– A new hybrid inkjet solution integrated in the press for individualised printing.

– Autoprint Smart for automated processes between large job signatures combined with super-fast make-readies enabled by DirectDrive technology and full inline quality control.

– High volume commercial printing with 64 pages printed in one pass on the ROLAND 900XXL perfecting press.

– A new press console and user interface requiring less operator attention and offering easier handling.

Smaller Presence, Bigger Story

Visitor’s to the stand may see the company occupying a smaller exhibit space as compared to drupa 2008, added Rothlaender, but we are sparing no effort in demonstrating to visitors our know-how and expertise as well as our determination to support the industry with our PRINTVALUE programme.

The PRINTVALUE programme increases the value of manroland sheetfed presses. Visitors to the booth will be able to speak with manroland sheetfed experts about how these value added services will enhance their businesses. These include:

– Printservices® technical support for total efficiency during the entire life cycle of a printing system.

– Printcom®, a full range of factory certified consumables that increase the efficiency of the printing process as well as production reliability.

– Printnetwork® networking and computer integrated manufacturing solutions; and finally,

– Printadvice®, advisory services from a partner that has had more than 160 years of industry experience.

The company will be offering visitors the opportunity to participate in daily organised visits to its Print Technology Centre in Offenbach, where they will be able to see four additional ROLAND presses in all formats up to XXL. This successful initiative from the last drupa will allow many visitors from around the world to gain a better understanding of the gigantic factories and the thrilling energy behind manroland sheetfed technology, concluded Rothlaender. We look forward to having those visitors join us for an exciting and informative day.