The company will unveil its new high speed punching and binding systems at drupa. The company is continually addressing new pressures in the finishing sector, mainly from the print-on-demand market, by introducing faster, more automated equipment. These new machines are designed to meet the needs of clients who use both professional and desktop solutions for small/medium and large print runs. The focus of Renz at drupa is the automation of each step in the production of loose leaf binding, the main focus being to provide solutions for processing variable print runs.

Some of the new machines to be show cased are as follows:

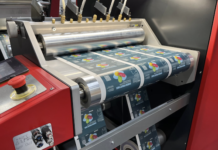

A fully automatic modular high speed punch, a first with an output of up to 40 000 punched sheets per hour. It has the ability to handle mixed stock including polyprop covers. Modular die insertion allows any loose leaf punch pattern to be punched. This machine bridges the gap between fully automated floor standing systems and heavy duty bench top punches. It complements the recently launched Renz wire binding machine, the Mobi 360 for the book, photobook and calendar work.

The new Inline fully automatic binding line with high speed punching and binding system, where book blocks are dropped on to the infeed (conveyor), punched and re-collated and fed automatically into the binder. It allows for less product handling and full automation of punching and binding, a world first. The Inline is also capable of punching and binding calendar sets with either nail hole or calendar thumb cut.

New Automatic Cover Turner linked to automatic lines:

This device automatically flips the back cover after the binding process and also spins every second book 180 degrees for level stacking. It can also be linked to shrink wrap tunnels or other boxing equipment. Great time saver aimed at high volume or fast production environments.

The INLINE 750 for formats of 750 x 800 mm with a performance of up to 4,000 bindings per hour ranks first in the industry. This inline system opens completely new horizons in wire binding with setup times of only a few minutes and numerous add-on alternatives, such as connection to a collator or the integration of an additional feeder for supplying external covers or inserts.

Also on show at the Renz stand will be a large selection of well established punching machines. From fully automated punches offering short setup times of less than five minutes to the companys most comprehensive range of heavy duty bench top/floor standing systems catering for both short/medium runs in standard and wide format options.

Renz continues to offer flexible and powerful solutions for any size print run, which can also be tailored to fit customer specific needs and reduce the labour to produce your product.

Daniel Pooley, International Marketing Manager, said, ‘Renz are proud to be leading the way in binding innovations with continual improvements to their binding technologies demonstrating their ability to react to customer demands’.

Michael Schubert, CSO Renz Group comments ‘drupa is one of the most important shows on the calendar, both in terms of the digital and associated technologies race but also in terms of deciding the future business strategy.’

Show highlights, what Renz will be producing:

Using the latest Renz punching and binding machines we will be producing wire bound books, tent cards and calendars in both short and long run work demonstrating the key features of its product range for the digital printer, printer, print finisher, professional bindery, in-plant, copy shop and bind on demand market.