Rectron showcased MakerBot’s leading line of 3D printers at a demonstration day held at its Midrand offices on 9 December. Some of the printers demonstrated include: the Replicator and Replicator 2 desktop 3D printer and Replicator Z18.

MakerBot recently announced the expansion of its global footprint to the African continent with the addition of Rectron South Africa as its first distribution partner in Africa.

MakerBot Replicator 3D Printers are powered by the user-friendly MakerBot Replicator 3D Printing Platform, which offers an onboard camera, plug and play features, app- and cloud-enabled workflow, and available Wi-Fi connectivity. Rectron distributes the MakerBot Replicator 2X Experimental 3D Printer, the MakerBot Digitiser Desktop 3D Scanner and MakerBot Filaments and accessories.

Rectron offers the growing capabilities of MakerBot’s 3D Ecosystem and Real-Time Prototyping to a wide community of individuals and businesses. MakerBot’s 3D printers and scanners are used as part of the design process to create models, prototypes and end products. 3D printing in real time on the desktop, with a MakerBot Replicator 3D Printer, revolutionises the design process and allows engineers, architects, industrial designers, artists, entrepreneurs and educators to recognise cost and time savings that significantly improve upon the expense and waiting times involved in traditional design processes.

With a MakerBot Replicator 3D Printer, Real-Time Prototyping enables creators to design and 3D print in a matter of hours or days rather than weeks. MakerBot believes that this speeds up the innovation process by empowering users to develop new designs at a much faster pace.

What also makes MakerBot products stand apart is the fact that the MakerBot 3D Ecosystem has been designed with the future in mind. While MakerBot 3D printing and scanning hardware is at the centre of the MakerBot 3D Ecosystem, the power comes from MakerBot’s continual updating of its software and apps to work toward constantly improving the 3D printing process and experience.

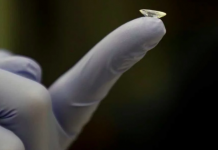

Likewise, the MakerBot Replicator Smart Extruder, a new feature of its newest generation of 3D printers, was designed to be easily swappable and replaceable not only to minimise downtown caused by filament clogs, but also to ensure that a new extruder can be easily swapped in when new filament materials become available.