Regardless of their size, region, or market, all printers must recognise the seismic shifts in print caused by digitisation. The challenge lies in deciding where to begin, given the rapid pace of so many radical changes.

The findings in The Print Horizons Report, published in March, are based on additional questions from the 9th drupa Global Trends Survey on the key technical and market developments likely to dominate drupa 2024. The report provides valuable insights and helps prepare all printers for the changes in the industry, with a large part focused on digitalisation but also sustainability and AI.

Executive Summary

The 9th Global Trends report, published in November last year, was remarkably positive given the challenges faced in the last few years. Printers and suppliers know that exploiting new technology is key to a successful future. The problem is how best to achieve this end. With this in mind, the 2023 Trends survey asked a range of questions on technology opportunities and priorities. From the replies, there were six key topics that were at the top of the printers’ priority lists for more research and investment.

1. The Changing Dynamics Of Analogue And Digital Production

The majority of printers will continue to use conventional print in tandem with digital production. If implemented effectively, the two methodologies should complement, not compete.

Faster More Efficient Conventional Print And Finishing

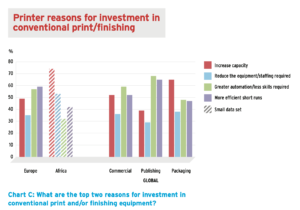

Most printers will look for more efficient conventional print and finishing at drupa 2024. The motivation will vary between regions (largely dependent on the cost of labour and the shortage of skills) and markets (largely dependent on the need for: greater capacity – packaging, lower costs – commercial and publishing, or fresh product development – functional).

Digital Print As A Core Production Method

Sheetfed toner technology still dominates the volume end of this market, but inkjet in its various guises is where most supplier effort is focused. Past simple conversations about the economic breakeven point between conventional and digital print have been overtaken by more sophisticated dialogues about how digital print can change a market, not just be economic for short runs and fast turnaround.

In terms of run length, there was no significant variation by region or market. Globally, 57% of printers reported that run lengths of more than 5000 sheets only occurred in up to 10% of their orders, i.e. rarely. Only 23% reported that it occurred with more than 25% of their digital print orders.

Regarding lead times, 48% of commercial printers reported that more than 25% of their digital print orders had a lead time of less than 48 hours, dropping to 32% among packaging printers and 27% among publishing printers.

‘In print’s history 15% of all pages printed are now digital. This is not a fast transition; it has taken 30 years. Digital print becomes successful when it is disruptive to an existing business model. Digital is then about value creation e.g. in the labels market, 20% of the value comes from digital production, but the volume is only around 8%. Replacement of offset pages since Covid when paper prices have doubled is effectively pricing yourself out of the market. Document printing is now more of a luxury product. The business model for low-cost pages has gone, it’s not necessarily going to digital. The industry is slowly evolving but we are doing it kicking and screaming,’ said Marco Boer, Vice President, IT Strategies, US.

2. Workflow And Automation

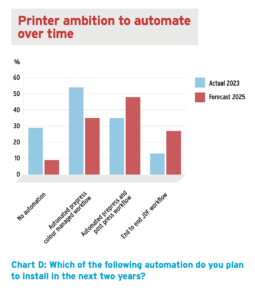

Print companies need to understand that investment in digital printing needs to go hand- in-hand with the digitisation of other business processes. End to end automation was described in the Global Trends survey as a progressive process, starting with no automation, then with automated prepress colour managed workflow, then automated press and post-press workflow and finally end-to-end JDF (or similar) workflow.

Globally 29% had none of the above i.e. had not started, 54% had prepress automation; 35% had press and post-press automation and 13% had end-to-end JDF workflow (only one option was allowed). There were regional variations e.g. 46% of Asian printers had none of the above, while only 24% of European printers had none. What was striking was the bold ambition for this to change in the next couple of years, as shown in the chart below.

To date many printers have made valiant attempts at automating individual workflows, but few have yet to tackle the bigger challenge of creating a single automated workflow. The time, cost and disruption of implementing comprehensive automation remains a big stumbling block, though there are an increasing number of integrated software solutions from suppliers ready to assist. Systems integration with customers and suppliers is proving to be an effective means of removing unnecessary labour and errors. As a result, data security and accreditation are now increasingly being demanded by customers and regulators. Marketing automation platforms are also offering printers cost effective communications to both acquire and retain customers or even their customers’ customers.

The Impact Of Artificial Intelligence

AI is already in use within the print industry e.g. to monitor and analyse machine performance data to assist predictive maintenance schedules. It could also be used to make better use of materials, reduce waste and help with quality control. The print industry should prepare for an influx of files with text and images created by AI and customer service interactions being automated and improved by chatbots giving real time updates and answering customer queries. All these aspects improve operational efficiency and manufacturing processes in the supply chain. All of us are at the beginning of a journey to understand generative AI’s power, reach and capabilities.

‘There’s an on-going interest in AI now. You see printers that are using it to analyse their data and workflow and also use it in customer service and marketing. There are uses of big data sets and AI in customising and highly personalising output using unusual data sources. I think AI is still a bit pioneering, but it‘s finding its way into leadership and also into the IT department,’ said Peter Van Teeseling, Executive Director Dscoop, The Netherlands.

3. Print Embellishment and Finishing

Investment in finishing is as important as that in print production, according to the latest Trends report. The shift towards short run and on demand production has changed the dynamics and requirements of the finishing department. One aspect that gets increasing attention is inline finishing and digital print embellishment. This in turn needs clients to be educated in the opportunities and costs involved.

When printers were asked ‘Why invest in print embellishment?’ there were mixed answers. 79% of European printers who selected this topic as a priority stated it was for customer acquisition and 45% for improved profit margin. The figures for Asia were almost exactly reversed: 63% profit margin and 37% customer acquisition. There was no significant variation by market, except that packaging printers put a higher priority on customer retention than commercial printers.

50% of packaging printers who selected this topic as a priority, stated that more than 25% of their turnover by value contains print embellishment compared with 28% of commercial printers. It is quite striking that 73% of suppliers were focusing their marketing efforts on cost effective production.

4. Web-To-Print

The Trends report data is a puzzle. It shows glacial growth in Web-to-Print installations. One commentator explained this as the effect of printers outsourcing work via cloud-based web-to-print platforms without having to invest in one themselves. Hence volume grows but not installations. What is not in doubt is that web-to-print can accelerate the pace of automation within a print business, taking on so many otherwise labour-intensive tasks.

Back in 2014, 25% of drupa’s global panel stated they had a Web-to-Print installation. In 2023, the figure is still 25%. We understand that some regions use less e-commerce for cultural, infrastructure and other reasons, but even in Europe the growth is glacial: in 2014, it was 27%, in 2023, it was 28%.

Globally of those who stated in this survey that online sales were a priority, 42% have had their e-commerce system for less than one year and only 30% have had it for more than three years. As to why companies are interested in installing and/or upgrading their e-commerce systems, this is influenced by the market sectors they operate in. While both packaging and commercial printers were broadly agreed as to the importance of customer acquisition and retention – 50% and 40% respectively, packaging printers were far more concerned with marketing differentiation (55%) than commercial printers (28%). It was the reverse for automation and workflow: 41% commercial and 23% packaging.

‘With W2P it is possible for printers to enter niche markets, own them and lock them down. W2P allows printers to play with dominance in the market; we manage 5000 products, in 241 locations in 104 countries. We use printers who are incredibly good at one type of print, e.g. book printers, photo products, business cards and they become synonymous with that sector. In this business model, competitors can also be partners through a global web enabled network,’ said Tim Cox, Business Development Director Cloudprinter, UK.

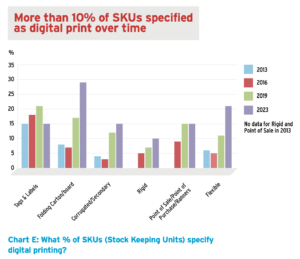

5. Digital Packaging And Labels

It is acknowledged by all that the packaging market has prospered through the period of digitisation and in consequence is receiving attention from many print companies of a different market tradition. At the high-volume end, conventional print continues to thrive, but as supply chains break up and become more complex and the number of SKUs grows, there are increasing opportunities for digital production.

‘I definitely see there is a huge opportunity in the digitally printed packaging space where printing what you need, where you need it and when you need it, will be accelerated through the growing Environmental, social, and governance (ESG) agenda of brands. 60% of the footprint of print and printed products is created by the transportation. So, if you can eliminate that or reduce it to the minimum, then suddenly it becomes a very viable alternative,’ said Peter van Teeseling, Executive Director Dscoop, The Netherlands.

6. Sustainability And ESG

Sustainability is not a fresh topic of interest, but one that no printer or supplier can afford to ignore any longer. Increasingly actions taken to increase sustainability are also good for the bottom line and are demanded anyway by customers, so it is a no-brainer to tackle the task with enthusiasm. 55% of all printers surveyed have a sustainability policy with specific goals and targets. This figure is true both globally and across all markets. This is an important recognition by the whole industry that the topic must be addressed effectively. It is no longer someone else’s problem – it is ours.

‘About 90% of the inquiries I now receive have a key sustainability component. We think this will continue to be a driver for brands in the coming years,’ said a packaging manufacturer in France.

ESG is more challenging, not least because there is no clear definition and the legislators are struggling to codify what is meant. Nevertheless, there is a trickle-down effect from large multinationals to smaller suppliers demanding this is given attention. For now, commentators advise that printers and suppliers start with what they understand, namely formalising their Corporate Social Responsibility (CSR) policy and processes.

The full Print Horizons Report is available here.

DRUPA

www.drupa.com