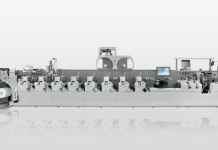

With the introduction of the new SigmaLine Compact as the latest innovation in digital print finishing, Muller Martini is setting another milestone in digital book block production. The expansion of the SigmaLine family is particularly impressive due to its minimal changeover times. For example, changing folding schemes, from four-up to six-up, takes just a few seconds.

On the opening day of the Printing United Expo, Bruno Müller, CEO of Muller Martini, announced the launch of the new SigmaLine Compact for the coming year. It enables digital printers to produce more end-products in a smaller space, with fewer staff and a lower waste rate. With the SigmaLine Compact, Finishing 4.0 meets sustainability in the production of books, brochures and magazines.

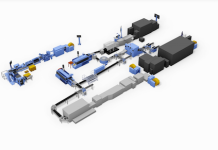

The SigmaLine Compact, which requires a production area of just 40sqm, not only sets new standards in terms of ease of operation and lower maintenance, but it also increases productivity and significantly reduces setup and changeover time. The fact that there is less than 10 m of waste generated when the folding scheme is changed is a weighty argument, especially in view of the current high material and energy prices.

Designed to handle digitally printed rolls up to 57.15cm (22.5 inches) wide, the SigmaLine Compact is the perfect solution for any digital printer producing semi-finished products for softcover, hardcover, thread-sewn and saddle-stitched print products in his Smart Factory. By covering all print finishing options, it sets new standards in terms of flexibility and takes the topic of Finishing 4.0 to a new level in conjunction with Connex. This is because this workflow system from Muller Martini ensures a completely automated production flow without manual intervention from prepress to the end-product. In other words: thanks to the SigmaLine Compact, which Muller Martini plans to launch on the market next year, digital printers can produce more books and brochures per shift with fewer staff. This gives them a significant economic advantage.

The highlight of the SigmaLine Compact, which complements the proven SigmaLine lll with web widths of up to 106.6cm (42 inches), is the folding process. While all known digital folders work with a sword, former or plow fold unit, the SigmaLine Compact uses Muller Martini’s patented air knife technology to process the signatures. ‘We have continuously improved air fold technology in recent years and use the same technology in the 22.5-inch line as in the high-speed area,’ said Ingolf Fritzsche. The Product Manager Digital Solutions at Muller Martini has maintained close contact with partners in the digital printing industry for years and is convinced “that companies operating in the digital sector have been waiting for this new solution.’

THUNDERBOLT SOLUTIONS

+27 11 657 7000

www.thunderbolt.co.za