Brochures, magazines and catalogues were the specialty of graphic arts company Silber Druck, which originally started in the publishing business, for a long time. Since the company launched its own online store, the focus has shifted from perfect binding to saddle stitching, which now accounts for a good 60 percent of the production volume.

In order to increase automation in both saddle stitching and perfect binding, the company, based in Lohfelden in the German state of Hesse, has invested in two new finishing systems from Müller Martini – a Primera PRO and an Alegro. Silber Druck prints up to 50 different jobs a day for customers in Germany, Austria and Switzerland – mainly using offset printing. The print runs are between 250 and 60,000 copies, with an average of 2500 to 3000 copies. The finishing systems have to be changed over frequently. As such, Silber Druck decided to invest in two new solutions from Müller Martini.

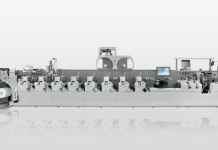

For saddle stitching, the choice fell on the 14,000 cycles per hour, whose features include the innovative Motion Control technology and the user-friendly interface with a larger touchscreen – for perfect binding on the 6000 cycles per hour Alegro, whose stations are directly driven and individually controlled and which, thanks to its high degree of automation, boasts short set-up times.

In addition to the fast job changes, which require only a few manual interventions, Lucas and Niklas Silber also found the wide range of size variability offered by the two Müller Martini finishing systems to be a major selling point. They inspected both machines at the training centre in Zofingen and at another customer’s premises before the final sales negotiations took place immediately after drupa 2024 in Düsseldorf.

The Primera PRO is already up and running, with the Alegro to follow in March. Silber Druck put the Primera PRO, which features five flat pile feeders, a cover feeder and a Perfetto compensating stacker, into operation last November – ‘to our complete satisfaction’, as Lucas and Niklas Silber emphasised.

‘With the two new machines, we are strengthening our position in the market because we now have significantly greater production reliability for sensitive delivery dates. We also wanted to send a signal to our staff that we believe in the future of the printing industry and our company,’ they said.

THUNDERBOLT SOLUTIONS

+27 11 657 7000

www.thunderbolt.co.za