The Prinova Saddle Stitcher achieves a cycle rate of 9000 copies per hour and is configured with eight individual feeders and a cover feeder.

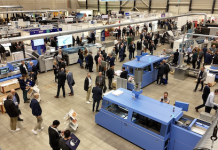

The Wograndl printing company in Mattersburg, Austria, used the last two years intensively to renew its entire production technology. A Prinova from Muller Martini was installed in the saddle stitching area, enabling the company to achieve a higher level of productivity.

Wograndl currently serves 700 customers from a wide range of industries, from local artisans to industrial companies and the public sector. Competition is particularly fierce in eastern Austria, which is also reflected in the prices that can be achieved on the market. ‘The challenge is to earn something even at this price level,’ said Managing Director Jochen Wograndl.

This also has to do with the fact that the company does not accept any compromises in a manufacturer’s performance promise when making investments. ‘With every purchase, we expect to achieve maximum productivity on all jobs. We don’t compromise on that,’ Wograndl emphasised. And that was also the case with the Prinova saddle stitcher.

Due to the attractive price/performance ratio,Wograndl decided to invest in a new Prinova. It achieves a cycle rate of 9000 copies per hour and is configured with eight individual feeders and a cover feeder. ‘For us, the Prinova is an investment in the future to secure production in the long term, both technically and in terms of quality,’ said Wograndl. Thanks to innovative individual feeders, he said, the saddle stitcher can be changed over in a very short time and is therefore ideal for short runs, but also predestined for medium runs.

In this context, Wograndl mentioned 10 to 15 minutes for a complete job changeover. Another technical highlight is the new ASIR PRO camera system. This recognises and compares the signatures by means of 1D/2D code and/or image comparison. This is a feature that rules out confusion from the outset when processing different language versions, for example.

However, a few teething problems had to be overcome before this could be achieved. ‘The fact that technical problems can occur during an installation was nothing new for us. The decisive factor is how a manufacturer deals with such a situation,’ he said.

THUNDERBOLT SOLUTIONS

+27 11 657 7000

www.thunderbolt.co.za