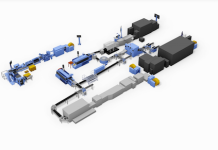

Goltze Druck GmbH & Co. KG can produce a much larger and more variable format product range for its customers – 80 percent of whom come from the region and some from neighbouring countries – on a new Prinova saddle stitcher with cover feeder and six flat pile feeders.

By investing in a new Prinova saddle stitcher from Muller Martini, Goltze Druck in Göttingen, Germany, will not only drastically reduce its makeready times, but will now also be able to produce in two ways; 90 percent saddle stitching and 10 percent perfect binding.

A glance at the figures quickly shows in which segment the production focus of the family-owned company, founded in 1951 and employing 30 permanent staff plus temporary workers in two-shift operation, lies. Although this was not always so pronounced (until a few years ago, the ratio was 75:25), managing partner Marko Fischbach nevertheless does not like to speak of a saddle stitching renaissance. ‘That would be putting it too crassly. But we are already noticing a trend toward saddle stitching due to reduced page counts and language splits, and are recording higher total volumes with declining quantities.’

The full-press operation with four presses is responding to this with the commissioning of a new Prinova this coming November. Currently, a 321 saddle stitcher purchased on the second-hand market a decade ago is in use. According to Marko Fischbach, this has a decisive disadvantage: ‘The makeready times for certain jobs are two hours, which is of course anything but in line with the market.’

Nevertheless, the old saddle sticher provided a decisive argument for choosing the successor model – which can be changed over to a new job in five to ten minutes (‘a quantum leap,’ said Marko Fischbach). ‘The fact that the 321 is still running so well is thanks to experienced service technicians and the excellent availability of spare parts. Muller Martini’s service performance has convinced us over the years,’ said the management of Goltze Druck.

The live demonstration of the saddle stitcher at Muller Martini’s Print Finishing Centre in Zofingen, where Marko Fischbach and Olaf Eckermann were on site, was also convincing.

Dual-purpose production benefits the company, which specialises in operating instructions, inserts, advertising brochures and classic commercial jobs with run lengths ranging from five (digitally printed) to 200,000 copies per job, particularly in the smaller formats. ‘Customers ask us all the time, ‘when are we going to start?’,’ said Fischbach.

The Prinova will also show its strengths at Goltze Druck for products with thin paper (down to 50 grams) and with language changes, because the new ASIR PRO camera system guarantees correct sheet sequencing. And another feature of the new saddle stitcher caught Goltze Druck’s eye: ‘The large touchscreen is really fascinating. The high level of user-friendliness will additionally shorten our processes.’

To be sure, the corona crisis did not leave Goltze Druck unscathed. There were markedly fewer orders in the events and travel segments in particular. ‘But fear is a bad advisor,’ said Fischbach. ‘We have a good, motivated team and the best customers. Many things will still change the printing industry. We look positively to the future. With Prinova, we are on the right track.’

THUNDERBOLT SOLUTIONS

+27 11 657 7000

www.thunderbolt.co.za