The company showcased a range of solutions aimed at digital and litho printers at drupa.

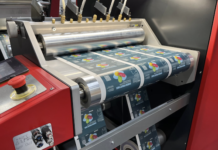

CardXtra Plus:

The CardXtra Plus has been manufactured to meet the needs of the growing number of digital printers who have asked for a highly accurate, low cost, easy to use multifunctional finishing device that can slit, cut and crease. With run lengths becoming shorter and jobs being personalised or printed with no overs it is essential to have an accurate, easy to use reliable finishing system; and that is exactly what the CardXtra Plus is.

It can feed sheets up to SRA3 in size and can trim, cut and crease in multiple positions. The accuracy of the new CardXtra Plus is the best available in the market with an accuracy of +/- 0.1mm which makes it significantly better than that of many more expensive units.

The addition of a unique registration mark allows the machine to track the image as opposed to the sheet edge, making it perfect for the digital environment. The versatile CardXtra Plus has the ability to take SRA3 sheets, trim them to A3 and crease them to produce finished A4 4 page brochures. Equally easily it can finish the job to A4 which can then be creased to make 4 page A5 leaflets or multiple creases for a wide variety of applications. The options are endless and with the million cut guarantee, the CardXtra Plus will be serving your business for

many years to come. The CardXtra Plus comes with three cutters as standard.

DocuMaster MFC

With today’s increased demand for high quality finished documents, Morgana are pleased to introduce the DocuMaster MFC. This is the latest in the DocuMaster range,

designed to eliminate tedious and time consuming operations by creasing the sheets as part of the feeding and booklet making operation.

With multiple feed stations, the design allows for feeding of specialised covers and booklet inside pages from separate feed bins while still allowing for creasing of cover,

centre or all pages of the book. The Documaster MFC incorporates the new ‘DYNATILT creasing system which automatically registers each sheet and adjusts the mechanism

to ensure an accurate crease position every time.

Creasing of covers, centre spreads or indeed all sheets in the book if needed, is simply programmed into the high definition touch screen control unit. Simplicity of operation

is key to finishing digitally printed work. Today’s on demand culture means run lengths are smaller and turnaround times are becoming shorter and shorter.

Controlled by a high definition touch panel, the DocuMaster MFC is given full instructions as to the book size, amount of pages and crease position etc. All settings and

adjustments are made using the high definition touch panel so operation couldn’t be simpler. An alpha numeric memory allows an unlimited number of jobs to be stored and

named as you choose. This makes job recall much easier as you can use your own job name and numbers for storage.

The DocuMaster MFC is ergonomically designed so that it can be loaded (on the run) and unloaded very easily from one position. The footprint is unusually small for a booklet-making system and it will fit into even the smallest of printrooms. The DocuMaster MFC utilises the latest advances in paper feed modules. These modules can be specified as suction feed only or suction and friction feed to a maximum of 4 separate feed stations. The paper is fed from these units using a centre reference sheet guide system and smart detection for sheet integrity.

The DigiBook 150 and 450

This series of machines is now suited to all sizes of digital printers, and all sizes of typical digital print run. The DigiBook 150 is capable of producing 150 cycles per hour and can bind publications with spine thicknesses from 2mm through to 50mm. The DigiBook 300 can bind up to 300 books per hour, whilst the top of the range machine, the DigiBook 450, can produce up to 450 cycles per hour with automatic cover feeding.

The DigiBook 150 is an entry level PUR binder and is ideally suited to traditional and digital printers who require short runs of PUR perfect bound books to a professional standard. The DigiBook 150 is equipped with a patented closed gluing system where the spine and side gluing is applied by a slot applicator for the utmost binding quality and accuracy.

Key product features:

• 150 cycles per hour

• Touch screen operation

• Binding length (spine) from 110mm up to 320mm

• Spine thickness from 2 to 50 mm

• Spine preparation by sophisticated notching device

• Paper chip extractor

• Patented hermetically sealed PUR application system for spine and side gluing with automatic glue cut-off

• Automatic cleaning and sealing of the glue head