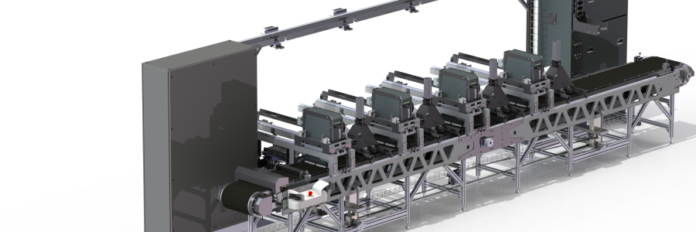

The Inkjet Test Platform allows optimisation of all process parameters and can be used to test printheads and different ink formulas, create various colour sequences to achieve the desired colour and vividness, experiment with different dryer systems and have access to an abundance of settings that influence the jetting behaviour and ink interaction on the substrate.

It can also be used to simulate a small-scale production environment to test new products before bringing them into a real production environment, proof customers’ applications or produce customer samples.

The platform is designed to test different print components and materials used in a digital inkjet system. All components can be easily rearranged to allow process parameter optimisation. It can test printheads, print quality, dryers, inks, substrates and even proof print applications prior to production printing.

The platform is targeted at customers that are developing inkjet inks, i.e. ink manufacturers or production companies that develop and iterate their own inks. The test platform allows altering all sorts of parameters that influence the process from printing to finished product and these processes can be reproduced on the test platform.

Other features include reduced risk, better process reliability, faster time to market and the possibility to run into a small-scale production. Especially ink manufacturers will benefit from the possibility to easily exchange the printbars of the system to work with inkjet heads of different manufacturers.

MATTITECH

https://www.mattitech.ch/