The company announced its next-generation HP Indigo 10000 Digital Press, the first B2 size format 750 x 530mm (29.5 x 20.9) electrophotographic digital press, offering superior-quality imaging in a size format suitable for nearly any application, at the pre-drupa event in Israel. It also announced the Indigo 20000 and 30000 wide-format presses as well as a range of new solutions, all of which will be exhibited at drupa, held from 3-16 May in Dusseldorf, Germany.

The three new larger-format HP Indigo models allow PSPs to expand into applications not previously addressable by digital printing, as well as to print more productively and economically for increased profitability.

The Indigo 10000 Digital Press is a 75-cm (29-inch) sheet-fed press that prints at speeds of 3450 sheets per hour in full colour, and up to 4 600 sheets per hour in Enhanced Productivity Mode (EPM). It combines HP Indigo offset-matching print quality with up to seven-colour printing and duplex and substrate flexibility. Available in early 2013, the printers larger sheet size accommodates efficient production of commercial applications not previously possible, such as die-cut folders and tri-fold A4 brochures, as well as larger books, such as layflat and coffee table books that can be difficult to produce on smaller sheets.

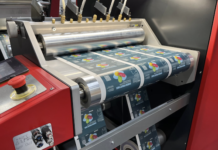

The Indigo 20000 Digital Press is a continuous-feed press designed for flexible packaging, capable of gravure-quality printing on films as thin as 10 microns with a printing frame of 73.6 x110 cm (29 x 43 inches) and has an in-line priming unit for industry-leading substrate flexibility.

The Indigo 30000 is a sheet-fed press designed for folding cartons, supporting substrates up to 24 points/600 microns and has an in-line priming unit.

Both packaging presses are scheduled for commercial availability in late 2013.

The company also announced three updated models of the current HP Indigo portfolio. The new model of the flagship HP Indigo 7600 Digital Press has a top speed of 160 pages per minute (ppm) in EPM – a 33 percent increase over the previous top speed, making it the fastest two-page digital sheetfed press available on the market. Other key innovations include automated detection of print defects in real time, special on-press effects for high-value applications such as raised print and textured effects that simulate embossing, and light black ink for improved monochrome photo images.

The HP Indigo 5600 is an enhanced version of the 5500, with a higher top speed of 90 ppm in EPM, a one-shot mode for printing on synthetic substrates, and greater application range to generate higher revenues with lower total cost. The Indigo W7250 is the other new commercial press, with 33 per cent higher speeds (up to 320 ppm in EPM and 960 ppm in monochrome).

The 7600 press, in beta testing at six sites worldwide, will be commercially available at drupa. The 5600 is available immediately, and the HP Indigo W7250 will be available at drupa. Most new features will be upgradable from existing HP Indigo models to protect customers’ investments.

New HP Inkjet Web press models:

The new high-speed HP T410 and T360 Inkjet Web Press systems offer increased print speeds of up to 244m (800 feet) per minute in monochrome – up to 25 per cent faster than previous models – while continuing to offer colour print speeds of up to 183m (600 feet) per minute. To achieve this improved performance, the presses feature new advanced inkjet printhead technology and nanotechnology pigment inks that can support higher speeds with no compromise in image quality.

The HP T230 Inkjet Web Press incorporates the new printheads and inks to increase print speed up to 122m (400 feet) per minute for both colour and monochrome, with full colour density for maximum quality.

These improvements will help PSPs reach new markets and increase profitability for high-volume applications such as book publishing, direct marketing and trans-promotional mail, where the HP Inkjet Web Press portfolio already has led a shift to digital printing. HP Inkjet Web Presses have produced a cumulative total of more than 10 billion pages since the first system was installed in 2009.

The HP T360 and HP T410 are expected to be later this year as new systems or as upgrades from the HP T350 and HP T400, respectively. The HP T230, expected to be available by the end of 2012, also will be offered as an upgrade from the HP T200 press.

New HP SmartStream workflow solutions

The company also announced its new workflow solutions. HP SmartStream Production Center is a production management system that addresses the challenges of producing and delivering high volumes of short run jobs, reducing turnaround time and increasing profitability. Available later this year, the system unifies multiple job streams, shows real-time, detailed end-to-end production floor status and enables PSPs to manage job progress and priority.

The new version of the HP SmartStream Production Pro Print Server, which fully supports the new B2 size format applications running at press speed. The brand new web-based user interface supports complex print server tasks. The version also includes automatic finishing planning and setup, supporting near-line and in-line finishing devices, as well as new automatic ICC profile creation per substrate. Other new capabilities include a new multi-rip architecture that significantly shortens job processing, enhances job streaming and batching capabilities, improves previewing, and offers additional imposition options.

There are also new versions of the HP SmartStream Director Web-to-Print solution, SmartStream Designer variable-data design and impositioning software, and the SmartStream Production Analyzer press monitoring solution.

New HP Print Module Solutions

The solutions provide an economical, module-based system for adding colour images, graphics and variable data to preprinted documents for more effective communication. Available in colour and monochrome, HP Print Module Solutions print up to 244m (800 feet) per minute and include complete workflow solutions for easy integration with existing equipment. By imprinting custom or variable content on direct mail or transactional statements such as credit card bills, customers can increase response rates for marketing campaigns. A new stitching feature extends the printing area for additional flexibility and scalability. The Module Solutions are expected to be available to order starting from 1 May this year.

Increasing its offering of more than 3 000 certified media types for HP Indigo presses, the company has added four HP Indigo preferred media partner agreements with Sappi, Avery Dennison, Mitsubishi and ArjoWiggins Graphics, extending customer choice and the ability to create differentiated applications.

The company also now offers HP Hiflex cloud-based software solutions, including MIS and web-to-print solutions, as a result of its recent acquisition of Hiflex. The solutions address most application areas, including commercial printing, sign and display, publishing, and direct mail.

Solution partners also introduced new media for the HP Inkjet Web Press models, such as Utopia Inkjet gloss media from Appleton Coated for direct mail and publishing applications.

ColorPRO papers will now include inkjet coated papers from Sappi and Appleton Coated, designed to deliver superior print quality with the HP Inkjet Web Press. Expanding the portfolio of HP finishing solutions, Muller Martini – a global leader in print finishing systems based in Switzerland – will demonstrate a new 1 066mm (42-inch) SigmaLine inline digital book production system at drupa, featuring increased operating speed to match the higher speed of the new HP Inkjet Web Press models.

New options for HP Scitex wide-format presses

The company has introduced new options to improve the versatility and productivity of HP Scitex wide format presses, including a white ink kit and an automatic loader for the FB7500 and FB7600 Industrial Presses, and a new version of HP SmartStream Production Analyzer for automatic monitoring of HP Scitex industrial wide-format presses.

The FB7500/FB7600 White Ink Kit and Hostert Automatic Loader expand HP’s solutions for its highest-volume flatbed printers with the option to add high-opacity white inks or stack-to-stack operation. HP SmartStream Production Analyzer is the only complete data analysis and operations monitoring software available for large-format PSPs.

Expanded PSP Services organisation

The company has also has expanded its global PSP Services organisation, providing a wide portfolio of service and support programmes to address mission-critical needs and help PSPs operate more efficiently.

With the extraordinary scope and scale of today’s announcements, we are fueling an unstoppable industry transformation from analogue to digital printing, said Christopher Morgan, senior vice president, Graphics Solutions Business, HP. Our new digital solutions strike at the core of the printing market and are able to meet the toughest requirements of world-class brands, publishers and print service providers.

Event attendees were also invited to HP Indigos Ness Ziona facility where they got an in-depth look at the new presses in Indigos laboratories.

The expanded HP Indigo digital press portfolio offers new levels of performance, image quality and application-driven opportunity to accelerate the analogue-to-digital print transformation and deliver profitable growth for customers.

HP representatives showcased the new Indigo 10000 at its Indigo Customer and Solutions Testing Centre. The representatives explained that the press incorporates SmartStacker, (developed by Horizon), a new B2-format slitter/merger/stacker system that can work in-line or near-line to the press, remove costly labour steps from the process, while significantly reducing job turnaround time. MBO, a specialist in folding technology, is also integrating its K-800 signature folder with the HP Indigo 10000 for in-line and near-line operation. The press also has a monitor which assists operators by showcasing the name of the substrates and how much paper has been loaded into the machine.

A customer panel was also held, with three of HPs customers, Jay Dollries (USA), Yukinori Okamoto (Japan) and Marco Perlman (Brazil), explaining how digital presses offer significant improvements in turnaround time, efficiency and marketing response. They also commented that the three new wider-format presses will allow print service providers (PSPs) to take advantage of applications not previously addressable by digital. The new platforms allow for penetration into the folding carton and flexible packaging markets. The Indigo technology gives printers all the versatility they need to help brands grow their business and to produce products in a wide array of markets, said Dollries.

.