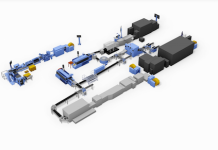

The Highcon Euclid 5C is a digital cutting and creasing machine that replaces a complex, expensive and slow die-making set-up and process with an in-house controlled digital system. It offers the improved delivery, flexibility and efficiency that display and prototyping company Rapid needs to meet growing production needs.

Despite world and industry wide delays and shortages amidst the pandemic, Rapid has ramped up their capabilities with Highcon’s Euclid 5C digital cutting and creasing machine to meet growing demand.

‘We’ve jumped three lightyears ahead with this technology,’ shared Chad Hartman, Rapid’s VP of Sales. ‘What once took us 22 hours to complete now takes us 45 minutes, which is exactly what our customers need: rapid delivery with high-rate efficiency. This will help ensure our clients can close deals faster.’

Mike Ciaramella, Highcon VP Sales and General Manager, Americas said, ‘Rapid has achieved considerable growth by giving its customers what they want. We are proud that they’ve chosen Highcon’s digital solution to take them in to their next step forward in building a competitive advantage and bringing greater value to their growing client base.’

In addition to improved technology to meet their client needs, Rapid has added a new facility focused on the e-commerce packaging sector and increased their personnel. ‘We’ve added a total of 27 positions here at Rapid to handle the increased capacity and new ventures, such as the packout and distribution of goods and displays we build onsite. 2022 will see continued investment in both staff and technology,’ said Kyle Jack, Rapid Owner.

HIGHCON

https://www.highcon.net/