Heidelberg’s next milestone in sheetfed offset printing is fully automatic printing plate logistics. Here the printing plates are provided fully automatically in the correct plate changing shaft and the used plates are removed – this is the only way to achieve consistently high productivity with short runs. As well as reducing the operator’s workload, process reliability is increased since damage caused by handling of the plates is systematically minimised. This increases the reliability of plate changes and reduces the risk of scratches on the plate causing paper waste.

‘There’s no point in just increasing the speed of the printing press,’ explained Rainer Wolf, Head of Sheetfed Product Management at Heidelberg. ‘That would be like being stuck in a traffic jam and expecting a faster car to solve the problem. Optimised, coordinated overall processes are a much more effective way of increasing productivity in the long term – they solve the traffic jam and deliver continuous schedulable productivity at the highest level. This is exactly where our focus lies.’

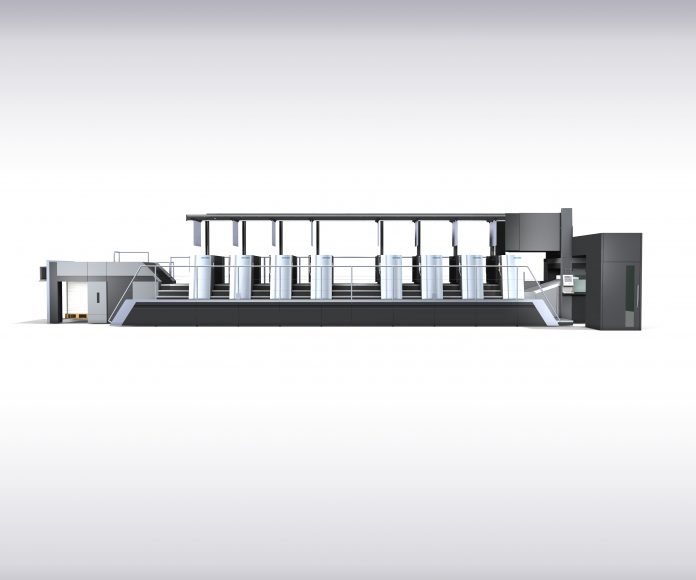

The new Speedmaster drupa 2020 generation will go into production with almost all model series as early as April 2020. All Speedmaster drupa 2020 models, in both small, medium, and large format, will be equipped as standard with the new Push to Stop functionalities and a cloud connection. This will enable all customer groups to enjoy the ever-increasing range of cloud-based software solutions and also benefit from future developments.

Industrialisation in printing companies is on the rise, and with it the requirement for ever better integrated and digitally controlled processes – from creation and production to delivery to the end customer. A growing number of orders need to be turned around within the shortest possible time. On top of this, the industry is looking for qualified specialists who can handle these increasing challenges. Digitalisation of operation and processes offers far-reaching productivity potential here.

Heidelberg presented the Smart Print Shop and the innovative operating philosophy Push to Stop back at drupa 2016. It has been consistently enhanced and will reach new levels at drupa 2020 thanks to further automation and many intelligent assistants. The new Speedmaster drupa 2020 generation and the Prinect print shop workflow will open up a new dimension in economy and competitiveness for offset printing.

‘At drupa 2020, Heidelberg will address the increasing job complexity in the press room with the simultaneous increase in requirements for operator qualification and improved productivity. In addition to increasing the output of the printing press itself, software-supported applications, intelligent user guidance, and autonomous processes as part of an integrated solution system – or as we say, ‘Smart Print Shop’ – will continue to grow in importance in terms of the competitiveness of the print shop’, explained Prof. Dr. Ulrich Hermann, Member of the Management Board responsible for Lifecycle Solutions and Chief Digital Officer at Heidelberg.

[sc name=”whatsapp_subscribe” ]

Heidelberg Graphic Systems Southern Africa (Pty) Ltd +27 (0) 86 142 4756 warren.jones@heidelberg.com www.heidelberg.com/za