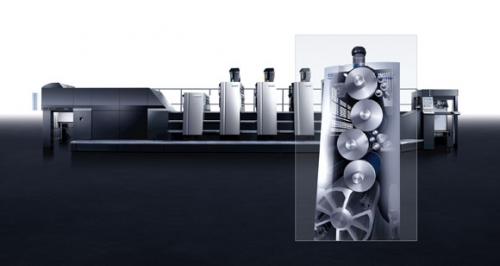

Heidelberg has introduced its game-changing Anicolor technology, now available in the 58x73,66cm (23×29 inches), six-up size. This is the ideal solution for printing service providers looking to grow their business in the 73,66cm (29 inches) short-run segment.

Anicolor technology combines the advantages of traditional offset with those of digital:

- Break-even to inkjet/e-ink based systems at less than 500 73,66cm (29 inches) sheets.

- Printing speeds up to 1,500 21x27cm (8.5×11 inches) sheets per minute or 15000 58×73,66cm (23×29 inches) sheets per hour.

- Compatibility with standard consumables at competitive prices means no forced choices for your consumables.

- Full substrate flexibility from onionskin to 32-pt. board, and up to three 27x43cm (11x17inches) tabloid panels.

Harald Weimer, president of Heidelberg USA said, The 73,66cm (29 inches) XL 75 Anicolor elevates the concept we call Digital 2.0 to a completely new level. This new reality extends the benefits of Anicolor technology from the 50,8cm [20 inches] environment into the 29 inches arena, and highlights the many exciting and potentially lucrative opportunities awaiting printers who want to capitalise on the global trend toward the printing of shorter runs with more frequent job changes in medium format. Especially for those who may be considering a 29 inches digital device, Heidelberg’s new Speedmaster XL 75 Anicolor press enables creativity and productivity in equal measure-without compromising the unique advantages of the offset process.

Heidelberg’s 50.8cm (20 inches) platform was proven for the Speedmaster SX 52, and the Anicolor inking unit now is also available for the Speedmaster XL 75, extending the range of applications into larger sheet formats. As such, the XL 75 with Anicolor inking technology is the optimum solution for the cost-efficient production of short- and very-short runs in 73,66cm (29 inches) format for commercial, label, package printing and point-of-purchase applications.

Anicolor technology is a revolutionary inking unit that reduces makeready waste to a bare minimum in terms of time and paper. Sellable quality can be achieved in as little as 10 sheets, with makeready times around six minutes per form. All the while, the user retains the proven advantages of the offset platform.

Bursting with performance-driving capabilities, the fully customisable XL 75 Anicolor is available in four to 10-colour straight and perfecting configurations, with full format flexibility up to 58x73,66cm (23×29 inches), the ability to handle stock thicknesses up to 32-pt, and inline coating. The press can be used with 4-colour process, extended multi-colour process as well as with PMS spot colours.

The XL 75 Anicolor also provides a number of key advantages over 29 digital production devices. With superior colour management, significantly higher production speed, and incredibly short make readies, the XL 75 Anicolor digital offset press opens the door to a huge variety of value-added applications with substantial profit potential.

Cost-conscious print service providers can tap those added profits without the click charges commonly incurred during the lease of digital printing equipment. Compatibility with standard inks means that the savings per sheet can be as significant as 90 percent, compared with inkjet/e-ink based devices.

Joerg Daehnhardt, product manager at Heidelberg USA noted, The XL 75 Anicolor offers digital efficiencies in short runs, and is competitive with conventional offset presses on longer runs, boosting capacity utilisation from the very beginning. The new press has a much wider run length window for cost leadership than traditional digital print engines.

Heidelberg has created a cost-to-print model, including an analysis of run length break-even and cost per job comparison, which can be customised to printing businesses.