GSE will present its solutions, both physically and virtually with an app, under the theme of ‘A.I. Your Inks!’ highlighting the performance benefits of automating ink processes and integrating them with existing software platforms.

At Labelexpo Europe 2023, the company will reveal additions to its range of ink dispensing systems and management software programmes for achieving repeatable colour quality and reducing ink handling costs, in the label and packaging workflow.

GSE Ink manager software provides dedicated programmes for automating, simplifying and accelerating every ink-related step in the print workflow, reducing human input, the risk of error and ink consumption, while enabling better forecasting and planning. The software is designed to track and manage inks through the more complex ‘circular’ workflow route that spot colour ingredients can take, involving the reuse of leftovers in new jobs.

Ink manager software programmes are available for processes including purchasing, inventory control, reusing press-returns, ink batch tracing, colour formulations and management reports, among others. The GSE software integrates seamlessly with existing ERP and cloud software, so ink-related data, such as formulations, job costs, and inventory levels can be exchanged with other MIS systems easily and instantly, without needing to manually re-enter information.

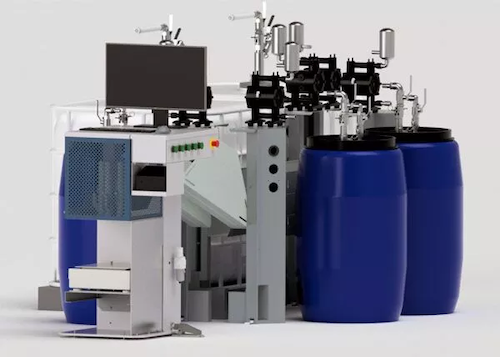

GSE’s Colorsat ink dispensing systems blend accurate spot colours on-demand, while cutting out waste, errors and delay in colour preparation, potentially reducing ink consumption by up to 30%.

They are extendible and tailored to volume and application needs, including for label, flexible packaging, carton and corrugated board printing. Colorsat dispensers are available for UV, LED-UV, low-migration, water-based and solvent inks, and flexo, gravure and screen processes.

At Labelexpo, a GSE Colorsat semi-automatic single ingredient dispenser will be introduced. This enables fast accurate and clean dispensing of colours, varnishes or coatings that are intended for printing without being blended: the ingredient is dispensed into a dedicated bucket with between 2kg and 20kg capacity, and then supplied directly to the press.

‘The economical single ingredient dispenser is designed to reduce ink-handling costs for medium-to-high volume process-colour and extended colour gamut printing situations, with water-based and UV-ink sets,’ commented Maarten Hummelen, marketing director and co-owner of GSE.

The dispenser may optionally include a computerised weighing scale, and GSE Ink manager software modules for ink batch traceability, cost control and order management. It can be installed in the vicinity of a printing press and easily be integrated in a network with existing dispensing systems equipped with GSE Ink manager software. In that case, the workflow can be further streamlined by using the new system as a station for weighing press-return inks as well. At Labelexpo, a single ingredient dispenser with five components, cyan, magenta, yellow, black and transparent white, will feature at the booth.

Hummelen commented, ‘Label and packaging printers should look seriously at automating processes wherever possible. Automation is key to driving down costs, and is the way to mitigate for skills shortages that the printing industry faces. With GSE’s automated ink dispensing and software solutions, integrated within the workflow, converters are best placed to assure consistent colour quality and safety compliance, in a sustainable, efficient and responsive way.’