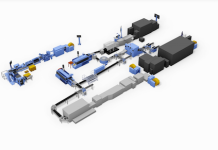

As part of a long-term programme of continuous development, Bak Gravür commissioned its flexo plate production facility this year, with the Esko CDI Crystal 5080 XPS being a cornerstone of the new site in Izmir.

‘For almost 25 years, we have invested in technology that helps cement our position as a world-renowned group of companies that creates value by achieving the best standards,’ said Gülşah Özoran, Area Sales & CRM Manager with Bak Gravür. ‘The quality of our output is of significant importance, both to ourselves and our customers. Our commitment to delivering the highest standards has helped us to earn the trust and loyalty of our customers, as well as a reputation for delivering both quality and value, something which is vital as we continue along our journey to becoming a global company,’ she said. ‘This investment enables us to take advantage of the latest innovations from Esko and further enhance our leading position.’

Bak Gravür has introduced the CDI Crystal line of flexographic solutions at its plant in Çiğli, in western Turkey’s Izmir district, adding the innovative plate imaging and exposure hardware to its new flexo facility.

‘Having worked with the Bak Gravür team for a number of years, we were thrilled to be able to build on our relationship and complete the company’s prepress and platemaking workflow with our plate imaging and exposure solution at their new flexo facility,’ said Mustafa Salur, General Manager Turkey and MEA with Esko. ‘The company uses a complete range of Esko software, including ArtPro+ prepress editing, Color Engine and DeskPack to ensure accuracy and quality, through to Automation Engine to standardise and automate workflows for efficiency and productivity gains. With the acquisition of the CDI Crystal 5080 XPS, the team has completed its digitised, automated and connected Esko ecosystem to both boost production capacity and ensure the best results for its customers.

‘The investment in the new facility underlines the company’s position at the leading edge in terms of using the most up-to-date technology available to guarantee its customers receive the best quality and service,’ said Mustafa. ‘The CDI and XPS Crystal technology from Esko delivers in terms of improved simplicity and optimised quality, ensuring the platemaking process, in terms of imaging and exposure, is now much less complex and has significantly fewer steps.

‘The integration of our workflow solutions and hardware technology means that the Bak Gravür team has complete control over the quality and performance of its plates and their subsequent print consistency.’

Combining UV main and back exposure, the award-winning Esko XPS Crystal exposure unit uses LEDs which do not require warm-up time and emit consistently stable light, producing excellent consistency of plate quality. ‘As well as this latest imaging technology, the team is using Esko Automation Engine, Device Manager, Color Engine and Imaging Engine to automate the workflow and further boost productivity and efficiency,’ said Mustafa. ‘This means Bak Gravür now has a full Esko ecosystem in operation, producing consistently high-quality plates.’

ESKO

www.esko.com