EFI Connect had more than 130 break-out sessions presenting the latest tips and trends across all the industry segments EFI supports. This includes sessions addressing the growing analogue-to-digital transformation opportunities using EFI’s industrial corrugated and packaging, textile and building materials/décor solutions.

During the 22nd annual Connect conference at the Wynn Las Vegas Resort, EFI highlighted state-of-the art digital print innovations that give print businesses more capability and profit potential in a range of market applications.

Display graphics inkjet offerings at Connect from the company’s leading-edge product portfolio included the new EFI™ Pro 30h production printer. Plus, Connect featured the first-ever live demonstration of the new EFI Fiery® FS500 Pro digital front end (DFE), the most-advanced print server in EFI’s 30+ year history, and the debut of the EFI Fiery Impress™ DFE, a scalable, flexible server and colour management solution for inkjet label and packaging applications as well as for inline manufacturing lines that need variable print.

EFI Connect also marked the debut of an innovative prepress product for display graphics businesses, EFI Fiery Prep-it™ software for the preparation, layout and automated production of print-for-cut jobs. Designed to address productivity needs amid continued labour shortages, this powerful and cost-saving true-shape nesting solution reduces the time needed to nest complex objects for wide format printing by up to 90%. Fiery Prep-it software also reduces media usage by 10% or more, helping to alleviate media supply constraints. With the media savings it generates, this affordable, effective software can pay for itself in four months or less, helping print shops become more competitive.

An early user of the software, Hossein Rasoulian, technical specialist at Irvine, California-based Super Color Digital, found that it reduced the time spent nesting jobs by 50%. ‘Fiery Prep-it is a very powerful and easy-to-use solution,’ said Rasoulian. ‘It can nest irregular-shaped jobs very quickly and uses media extremely efficiently. We can also fully automate our print-and-cut process using Prep-its integration capabilities to get a high quantity of jobs produced accurately, without errors.’

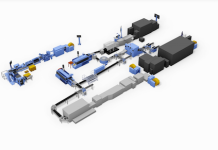

The newly launched, 3.2m wide EFI Pro 30h UV LED printer at Connect prints up to 230 square metres per hour, offering a combination of speed and efficiency that makes it an ideal hybrid flatbed/roll-to-roll superwide format solution for businesses targeting production display graphics as a growth opportunity.

Designed to provide broader application capability, versatility and profit potential, the printer maximises productivity by printing large boards or multiple small boards continuously. Switching from rigid to flexible media with the printer is easy, and the Pro 30h can print on dual rolls, giving users high throughput and the ability to run multiple jobs simultaneously.

Connect attendees also learnt about the accelerating signage production opportunities empowered by EFI’s advanced Super High Speed class of superwide format inkjet printers. Conference sessions exploring the faster, better, state-of-art possibilities in high-quality display graphics showed how these solutions can drive digital production to new, higher levels.

This power trio of printers included:

· The EFI VUTEk® XT, a robust, 3.2m wide hybrid solution with available media handling automation that prints at speeds above 375 boards per hour. A new and unique CP5G system for the XT model delivers complete ink circulation, superior dot placement, 5-picolitre drops and greyscale imaging for near-lithographic quality without expanding beyond four-colour CMYK ink sets.

· The EFI VUTEk Q5r, a 5.2m wide UV LED inkjet production workhorse that is the fastest roll-to-roll printer in its class, thanks to throughput speeds that reach 672 square metres per hour. Users can establish a complete print-to-finished-graphic workflow on the VUTEk Q5r with in-line slitting, trimming and other value-enhancing options, including a new in-line visual inspection system available this year.

· The EFI Nozomi 18000+ LED single-pass printer for display graphics, a groundbreaking 1.8m wide signage solution. Available with up to six colours, plus white ink, it prints on synthetic and paper-based media at up to 1000 sheets or boards per hour – a speed that is three or four times faster than the most productive shuttle-based/multi-pass display graphics printers.

Connect is also where print professionals witnessed, for the first time, the FS500 Pro platform scheduled for release this quarter with new office and cut-sheet production systems from many of the world’s leading digital printer manufacturers.

The advanced, new DFE platform for commercial and cut-sheet digital printing RIPs graphics-intensive jobs up to 50% faster than previous EFI Fiery DFEs. A Fiery JobExpert feature for the DFE can streamline job prep tasks, saving valuable time by automatically choosing correct colour and imaging settings. Fiery FS500 Pro also provides an extensive collection of additional, innovative new features that address top challenges print businesses face, such as shorter runs, faster turnaround times, less experienced staff, increased security standards and the need to reduce costs.

EFI also expanded its leading DFE technology offerings at Connect with the worldwide debut of the Fiery Impress DFE, a scalable, flexible off-the-shelf server and colour management solution. The Fiery Impress DFE helps equipment manufacturers achieve outstanding productivity and image quality. Specialty inkjet equipment vendors with low unit volumes, as well as single manufacturing lines that want to add in variable or personalised print with a print bar, can expand their digital offerings with this innovative new technology.

The Fiery Impress DFE can drive entry-level, mid-range or high-volume inkjet equipment on a range of hardware platforms. For example, users can output TIFFs to a storage location for entry-level CMYK digital presses, or produce rapid, RIP-while-printing output of variable-data content to high-volume, continuous-feed 7-colour digital presses. Fiery Command WorkStation®, an operator interface for job management, is standard with the Fiery Impress DFE. A wide range of integrated software options are also available, including prepress, colour management, workflow automation, and EFI IQ™ cloud analytics.

‘As the industry works to regain its footing after a very difficult couple of years, EFI customers and partners came to Connect to learn about the actionable strategies and important tech developments that could be essential to their future success,’ said Ken Hanulec, vice president of worldwide marketing, EFI. ‘And, more than anything, this year’s conference reflected the community, collaboration and innovation that print businesses can use to capture the growing opportunities of the industry’s analogue-to-digital transformation.’

Along with the latest EFI and eProductivity Software offerings on display, this year’s conference also featured exhibits and technologies from many participating partners, including: Aberdeen Fabrics; the Cal Poly Graphic Communication Department; the Clemson University Department of Graphic Communications; Duplo; Esko; ISCorp; LoyaltyLoop®; the Mariano Rivera Foundation; Plan Prophet; the Print and Graphics Scholarship Foundation; Print Speak; PRINTING United Alliance; Progress® Software Corp; Ricoh® USA and Zünd®.

EFI

www.efi.com