Dr. Sean Smyth, analyst and consultant, Smithers, and writing for drupa, said digital packaging offers many opportunities for commercial printers looking to move into new sectors as many traditional print applications continue to decline. The same dynamic is encouraging more equipment suppliers to offer digital printing systems for labels, corrugated, cartons, flexible packaging, rigid plastics, glass and metal packaging.

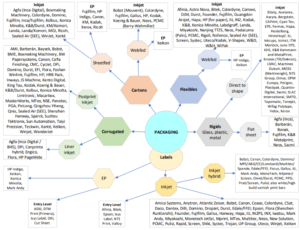

The figures show how the suppliers of digital print equipment for labels and packaging have developed since this technology map was first produced in 2019. There has been a steady stream of new entrants, from established analogue print equipment suppliers and new providers leveraging their digital print expertise.

On top of these there are digital overprint systems and sophisticated bespoke integrations, some operating as a part of manufacturing and filling lines. While there has been consolidation in the supply side, it is striking that there have been few exits from the sector, with the high number of players now competing in the wide range of packaging applications, offering new capabilities and functionalities, with steadily increasing productivity and lower costs.

Well, the good news for us print techies is this diagram will get even more crowded this year. Smithers tracks the developments in this sector, publishing reports and running conferences on digitally printed packaging.

Today quality, reliability and productivity are no longer issues for inkjet and electrophotography packaging presses. At drupa there will be sheetfed inkjet machines offering the equivalent of process colour sheetfed litho at speeds of 11,000 B1 sheets per hour, while web presses offer speeds in excess of 400m per minute up to 2.8m wide. These are mainstream alternatives to litho, flexo and gravure alternatives.

The printhead and press manufacturers are developing methods to eliminate inkjet artefacts, compensating for nozzle outs and deviations in real time that extend the life of the heads and machine uptime. Inkjet will be the real winner, with faster machines being shown, particularly in flexible packaging. Ink technology is improving, with UV and water-based inks being employed for specific applications. There will be more highly pigmented formulations helping reduce the ink film thickness while lowering the total cost of ownership, further boosting the share of digital print.

It is not just printing. Some vendors will show single pass, highly automated systems to print and finish corrugated boxes, cartons and flexibles in a single pass. The enabler is the combination of digital print with digital finishing. These will feature automated control systems that drive the press, measure and check the print then track through finishing which may be coating, laminating, cutting, creasing, folding and gluing, together with a wide variety of embellishments. The digital front end controllers are becoming increasingly powerful, automating and driving the digital print unit while at the same time measuring and controlling quality and then to set and drive the finishing technology. This approach helps replaces the traditional skills of press minders and finishing journeymen operators, which is important as skilled labour resources become scarcer.

While new digital presses are the shiny and sexy headline grabbers, even more important is the enabling workflow software. The only way of making money from a digital press is to produce saleable output and powerful workflow is vital to prepare the artwork files and keep the print queue well stocked. This can be a barrier for packaging converters entering the sector as many do not have the necessary prepress and data handling skills.

Workflow will become increasingly collaborative, with new designs produced and approved, then loaded into job queues for automated colour management and imposition with no manual involvement at the converter. The MIS is linked, ordering substrates and planning the production on printer and finishing to meet the customer requirements and optimise capacity at the converter.

Digital workflow can be daunting for packaging converters used to handle a few large jobs but it is the way of the world. Companies can explore solutions at drupa to simplify supply chains that will be key to future success supplying packaging and labels. The market leaders offer a broad variety of creative software. They will show new methods to automate the repetitive processes involved with packaging design, approvals and prepress taking time and cost out of the process. Other players will offer specific solutions for integration and to optimise colour management, imposition and providing variable data capability.

All these packaging developments are ultimately driven by end customer expectations, or rather demands. In the increasingly connected world, these demands and expectations are changing, with more engagement and interaction to improve the consumer experience of the brand. Digital printing allows brands to make content decisions later in the supply chain, closer to the consumer that helps packaging offer additional valuable functions. These additional functions move packaging beyond the traditional containment and protection functions, with information and promotion. A unique digital print can be connected to the cyber world, opening new opportunities of logistical efficiency and greater consumer engagement.

DRUPA

https://www.drupa.com/