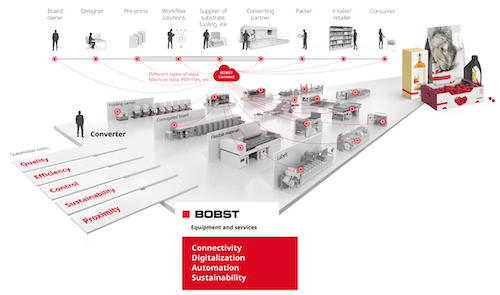

BOBST has unveiled its latest advancements across all industry segments such as flexible packaging, labels, folding carton, corrugated board, and services, to help customers to thrive in the current and future packaging environment.

At drupa, visitors to the stage area will have the opportunity to find out how BOBST is bringing its vision to reality through a live-show experience on a ‘concept machine’. BOBST’s industry storylines will be featured through key solutions along the end-to-end production process.

The company has announced the launch of two major new features for BOBST Connect, the company’s cloud-based digital platform that improves productivity. Workflow with Job and Recipe Management empowers customers to seamlessly integrate BOBST machines in their production and design workflows and benefit from bi-directional job and recipe data synchronisation for fast set-up and increased productivity. The Energy Monitoring feature allows customers to measure their energy consumption and costs in real time.

Reinforcing its credentials as a strategic partner, the company has also announced the development of BOBST Application Management across the four industries, a hands-on innovative consulting service focusing on workflow automation, colour and process optimisation, end-to-end converting improvements as well as regulatory compliance, addressing the needs of converters and brand owners.

The company has stated that all new machines purchased in 2024 will benefit from at least between 10% and 20% efficiency and productivity improvements, from reductions in waste, substrate and energy usage.

Below are the newly announced highlights from each industry sector. Several of these will be officially launched at drupa 2024.

Folding Carton

EXPERTCUT 106 PER is a new generation die-cutter that increases performance up to 20% with increased throughput and positive sustainability impact. The EXPERTCUT 106 comes equipped with breakthrough new functions such as the ACCUPLATEN, a new system that will reduce the patching effort during setting and increased running speed.

TooLink brings converting into the digital world. It is a platform that connects machines and tooling and brings together the entire converting process to transform production flexibility, job turnaround times and overall productivity. Soon available on folder-gluers, TooLink will simplify and shorten the changeover by automating recipe management. In addition, it will check the quality of tools and ensure the quality of production.

Corrugated Board

Robotic solutions: an important milestone in bringing its vision to reality, BOBST now offers a wide range of robotic solutions for both loading and palletising, which will allow configuration of complete and seamless production lines for customers.

FFG portfolio extension: machines with what matters for RSC converting: printing (1/2 colours) and die-cutting with flexibility in production, robust design and short set-up time with the top printer. New JUMBO: from simple printer-slotter up to full line, including stitching, taping and inline folder-gluer.

MASTERFLEX HD+: new generation of the reference flexo printer, for unmatched productivity and highest quality. By incorporating a new feeder, upstream pre-feeder and stacker outlet, the MASTERFLEX HD+ achieves a staggering throughput of 15,000 sheets per hour, covering an impressive area of 53 million square metres per year. This enhancement results in a remarkable 8% boost in productivity.

BOBST offers a wide range of services and digital solutions to power performance with expertise and digitalisation. New additions include:

• The new, updated BOBST Connect: providing digital solutions to prepare, produce, react to, maintain, and optimise the production workflow of a job. BOBST Connect is a one-stop shop for increasing productivity capability at every stage.

• Extended capacity of the EMEA Logistics Hub: the Genk facility enables the ability to serve customers with speed and efficiency. Its capacity is being extended by more than 60% this year to increase customer reach and increase service quality, while ensuring the site meets the highest sustainability certifications.

• The Remote Assistance service, which includes video with augmented reality support using TeamViewer, allows fast, high-priority remote resolution of electrical and mechanical problems, and reduced downtime. The feature now includes live caption and chat translation.

• Operational Excellence Programme: customers get support to drive continuous improvements with combined data analysis, process expertise and proven consultancy.

BESWICK MACHINERY – BOBST AUTHORISED AGENT SOUTHERN AFRICA

+27 11 433 2686

bmmarketing@beswick.co.za

www.beswick.co.za