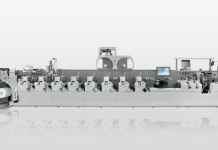

The installation of a CL 850D laminator will ensure high performance cold-formed foil pharma packaging to Oai Hung, the subsidiary of Constantia Flexibles in Vietnam. The CL 850D is due for delivery and installation in the cleanroom of the company’s state-of-the-art production facility in Ho-Chi-Minh City in the second half of 2018.

Oai Hung, a company specialised in the production of aluminium blister foil and rigid film for the pharmaceutical market, as well as foil-based lids for dairy packaging, is pivotal to the Constantia Flexibles Group’s expansion in South East Asia. The site is dedicated to serving these high-end market segments, which drove the decision to invest in new equipment.

Cold-formed foil packaging is a complex process both in terms of the actual material functionality and compliance with pharma regulations, and in terms of process workflow, operational efficiency and profitability. This is why Constantia Oai Hung and BOBST collaborated closely on the features of the CL 850D in order to meet all the exact specifications relating to output requirements and expected machine performance.

The most complex type of production run on the CL 850D will be an OPA-Alu-foil-PVC triplex compound structure. The guarantee of 100% barrier to external agents and the resistance to stress and puncture of the material, is an essential part of the process even under extreme conditions. To ensure high de-lamination stability and additional protection of its barrier properties, the Alu-foil substrate is lacquered with an adhesion-enhancer primer before undergoing the actual lamination process.

The machine is equipped with the semi-flexo coating trolley, which is the same standard solution fitted on BOBST customised coating lines dedicated to aluminium lacquering. The two-roller vertical solution developed by BOBST enables a higher coating speed to guarantee only superior quality coating whether it be solvent-based adhesives or lacquers. Both processes can be carried out on Oai Hung’s CL 850 without having to change the coating trolley. It also provides higher uniformity and a better coating distribution across the entire web width.

One of the hallmarks of the BOBST web-fed technology is the web handling capabilities of all its equipment. This is even more critical when handling thick unsupported alu-foil substrates, first during the lacquering stage and then the subsequent lamination process, without creases or any other web winding defect.