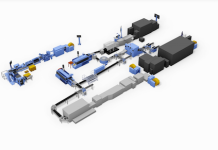

The EXPERTFOLD 165 is one of BOBST’s most popular folder-gluers. Designed as a modular machine, it can handle a wide range of corrugated or litho-laminated boxes and can be equipped with a variety of peripherals and devices to offer packaging converters super versatility and enhanced performance.

Scotland’s largest independent corrugated packaging manufacturer, Cullen Eco-Friendly Packaging, has extended its product portfolio and increased capacity and production reliability after investing in two EXPERTFOLD 165 folder-gluers.

Celebrating its centenary in 2021, Cullen’s significant legacy began with high-end display boxes for the local whiskey industry. Today, a trailblazer in sustainable packaging, it operates from a 56670sqm (610,000 square foot) site in Glasgow, where it has manufactured over one billion corrugated packaging and moulded pulp products that have been distributed to more than 33 countries worldwide.

The double EXPERTFOLD investment builds on a long-established partnership with BOBST as Cullen already operates two BOBST die-cutters. Production director, Ryan Kelly said, ‘Demand for corrugated packaging has rocketed in recent months. This is due to an increased requirement for e-commerce solutions in addition to the increased consumer demand for more sustainable packaging.’

‘As a company, we are committed to a programme of investment that allows to us to be at the forefront of corrugated manufacturing, while significantly increasing volume over the next five years to meet demand. The purchase of these two EXPERTFOLDs has enabled Cullen to increase our production of high-quality packaging innovations for our customers, whilst simultaneously achieving multiple operational benefits.’

Following a series of new efficiency-boosting features in 2020, the BOBST EXPERTFOLD 165 offers up to 15% set-up time reduction, and improved flexibility and accuracy with corrugated packaging. Additional command panels have been incorporated at each stage of operation, enabling greater control along the full line and reducing changeover times. The ACCUFEED was upgraded to include a new pneumatic locking feature for feeding ramps and the integrated blank aligner was innovated to have wider conveyors for perfect quality folding on heavy flutes. Meanwhile, on the folding section, customers can now opt for larger folding belts, a heavy-duty central conveyor and a dedicated pressing device, specially developed for double wall board. These changes enable perfect, more efficient handling and processing of larger or heavier blanks or material.

Kelly said, ‘The improvements that have been made to the latest BOBST EXPERTFOLD 165 translates to more versatility and reliability in what we can offer our customers. The implementation of these machines has helped streamline our manufacturing process providing a number of commercial gains including higher throughput, less downtime and increased product quality.’

Kelly concluded, ‘We have a long-established relationship with BOBST and know the strength of their technology first-hand. When considering an upgrade to our machinery, we chose the BOBST EXPERTFOLD 165 folder-gluers for their build quality, safety systems, versatility and considerable throughput.’

BESWICK MACHINERY SHEET FED DIVISION

+27 11 433 2686

bmmarketing@beswick.co.za

www.beswick.co.za