BOBST reports that drupa 2012 has been its most successful trade fair ever. The three BOBST business units – Sheet-fed, Web-fed and Services – each generated record sales with their innovative products and services. The new uniform branding for the whole company also triggered positive emotions among both customers and employees.

From the very start, the extremely confident atmosphere on the exhibition stand in Hall 10 travelled all the way to BOBSTs headquarters in the Swiss city of Lausanne. In light of the thousands of leads received – including more than one hundred for firm projects due to take place over the next three months – the company is expecting very strong trading in the wake of the exhibition. The company plans to use the momentum generated in Düsseldorf to continue to successfully implement its company-wide transformation process over the coming years.

Over the last few years, our entire team has worked very hard to pave the way for our companys future. The results of this years drupa confirm in no uncertain terms the benefits of these efforts and commitment. Im very proud of our employees great achievement, said BOBST CEO Jean-Pascal Bobst at the close of the exhibition in Düsseldorf. We intend to use this success and renewed motivation to further consolidate our companys position in the global marketplace.

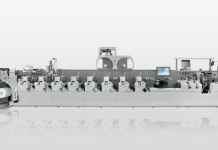

BOBST unveiled a wide range of trailblazing innovations at drupa 2012. To avoid overloading its exhibition stand, the company made a conscious decision to focus on four machines, each incorporating a range of innovations: the new 20SIX flexo printing machine platform for the production of flexible packaging, the new EXPERTCUT 106 PER flat-bed die-cutter, the MASTERFOLD 110-A3 folding box gluing machine and the SL 1000 solvent-free, high-speed laminating line.

Many customers from all over the world also took advantage of drupa to see machines such as a 10-colour F&K 20SIX flexo printing press in live operation at BOBST Bielefeld, as well as a MASTERFOIL 106 PR high-end foil stamping press at Druckveredelung Köch & Glasder GmbH in the town of Neuss, not far from the exhibition. BOBST also presented details of its new EXPERTFOIL 142 large-format foil stamping machine at drupa. The Hawkeye Registron System for in-line quality control of production with metallic foils and the smartCOL closed-loop solution for colour control in flexo printing had already made their debut shortly before the exhibition.

In addition, in the autumn of 2011 BOBST had launched ACCUCHECK, the worlds first integrated quality control system for folding-box gluing machines and GYROBOX, the first turning module for the corrugated board industry. In Düsseldorf, BOBST announced the launch of an industrial digital sheet-fed printing press for packaging production planned for the summer of 2013. Operating at high production speeds, this unit prints materials with water-based inks in photo-realistic quality, typically used in the packaging business.

In total, more than 100 transactions were concluded on the BOBST stand at drupa. For the Web-fed business unit, the machines from the new F&K 20SIX platforms attracted particular interest. This business unit also sold several vacuum metallization machines, laminating machines and gravure printing lines. For the Sheet-fed business unit, sales were distributed relatively equally between flat-bed die cutters, folding-box gluing machines, foil stamping machines and inline machines for the production of corrugated board packaging.

The main attractions for the Services business unit included new remote services such as the MOBILE PORTAL app for machine monitoring using mobile terminals such as smart phones and Tablet PCs, and the Boost my BOBST programme including upgrades for older machines. Not forgetting intelligent tools designed to increase the productivity and security of production processes, including the Braille Dot Checker which automatically checks each individual dot of Braille on folding cartons. The guiding aim behind all these innovations is to support customers in their ongoing quest to increase the productivity and efficiency of their production processes, exploit new opportunities for growth and improve their environmental performance indicators. The key themes include reducing waste, shortening setting-up times and ensuring error-free production including high colour accuracy.

One major highlight to emerge from BOBSTs successful performance at drupa 2012 was the fact that more than 40% of the machines sold during the exhibition went to new customers. This unusually high figure confirms the effectiveness of the group strategy we introduced two years ago. We have managed to increase our companys attractiveness for the existing customer base, while at the same time convincing potential new customers that BOBST is the right partner for their packaging production operations, said Jean-Pascal Bobst.

After Germany, India purchased the highest number of BOBST machines at drupa 2012. Brazil and China also ranked among the top six purchasing countries for the company at this years drupa. This geographic distribution helps to explain the high proportion of new customers. In emerging markets, manufacturers of all kinds of goods are also following the trend towards high quality packaging apparent in developed industrial countries. Boosted by this continuously increasing demand for top quality packaging, many packaging manufacturers are experiencing rapid development. This background also helps to explain another noticeable feature of visitors to the companys stand at drupa: the proportion of branded good manufacturers was higher than ever before.

Its attractive exhibition stand and dynamic new branding also contributed to its success at drupa 2012. The company unveiled its new logo, replacing the groups previous brand names, under the slogan BOBST One Group, One Brand.

This years drupa exhibition also gave the company an opportunity to demonstrate to customers the full benefits of its far-reaching transformation programme. BOBST customers around the world are now reaping the benefits of the slimmed down organization, reduced response times in Sales and Service, the effectiveness of the new Services business unit and the technological synergies of the new platform strategy, allowing BOBST to select the best technologies as platforms for the development of new machines, solutions and services. Not forgetting the companys clear commitment to permanent innovation, focusing on customers current and future needs. The results achieved in Düsseldorf clearly show that across the different segments of the packaging industry both existing and new customers have recognised these benefits and rewarded them with their orders.