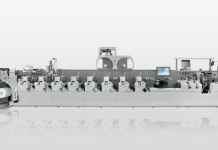

The BOBST AMBITION A2 folder-gluer is able to handle carton board up to 800gsm and corrugated N, F and E flute type. It can produce straight line as well as crash-lock bottom boxes at a maximum speed of up to 300m/min. India’s Innova Printing and Packaging has seen production of its in-demand micro-fluted boxes double after investing in the BOBST folder-gluer.

The folder-gluer is the second BOBST machine that the company has invested in. Initially, the target market was for smaller sets of boxes but micro-fluted boxes, of various sizes and shapes, are proving to be the fastest-growing product for the business, explained Akash Pabbi, one of the three directors at Innova. Vijay Pabbi and Akshay Sai are the other two directors.

The three young entrepreneurs took charge of the company, which was established in 1985, in 2018 and have since grown company sales threefold. In 2019, the company moved to a new facility in Harohalli, Bengaluru Rural, which was specifically constructed to use space in the best manner. Equipped with offset printing machines and post-press machinery to support mono cartons and micro fluted cartons, the company added a BOBST NOVACUT die-cutter in 2019, before investing in the BOBST AMBITION 106 A2 folder-gluer. As well as specialising in mono cartons and micro-fluted cartons, the business has the capacity to convert 500 tonnes of paper and paperboard each month. A team of quality control experts inspect every stage of production to ensure that the products adhere to international quality standards.

After assessing existing production operations and new products coming onto their lines, the three directors spent time considering their next investment to ensure they could continue to deliver quality and excellence. ‘We had a vision to create capacity to cater to the new demand that was coming from the market. Investing in kit that would help us to finish our products better, as well as serve our clients with better quality led us to invest in the BOBST NOVACUT,’ said Pabbi.

The BOBST NOVACUT die-cutter can handle a maximum sheet size of 1060 x 760mm at a speed of 8000s/ph and is capable of handling paper, carton board as well as corrugated boards of up to 4mm. Vijay Pabbi said that the BOBST NOVACUT soon proved that it could withstand market pressures with the onset of the Covid-19 pandemic. It fell in line with the sudden threefold surge in packaging demand during the pandemic. It was quick and the quality was superb. We had no complaints at all. All the maintenance activities were carried out on time’

In terms of productivity, the BOBST die-cutter gave a solid advantage over the manual punching machines. ‘What used to take 14 hours to produce with 14 persons, can now be produced in an hour with just three people operating the machine,’ said Sai.

However, that presented a new challenge for the Innova team: how could they keep up with die-cutting production and glue all the cartons, particularly the corrugated cartons? The company’s existing Indian machine was unable to handle the extra work. ‘That’s when we decided to invest in the BOBST AMBITION folder-gluer,’ said Sai.

‘The quality was slightly inconsistent with the previous machine, but we were able to resolve the issues such as fishtailing and cross-pasting with the BOBST folder-gluer. The two BOBST kits complement each other. We have been able to up our production levels to handle 500 tonnes per month,’ said Sai.

Pabbi added, ‘We are very satisfied with BOBST in terms of the support we have received whenever we faced any issue and their service engineers along with the sales team are well trained, which has helped us in terms of knowledge and learning about the machine.’

BOBST

https://www.bobst.com/