BOBST has a vision where the packaging supply chain becomes fully digital. The company has announced its latest innovations in printing, converting, services and performance to help converters and brand owners take a big step towards the digitalisation of the packaging supply chain.

‘The packaging industry is in the midst of a digital revolution, which is forcing every company to innovate, challenge their approach, think end-to-end and digital, and leverage networks and platforms to deliver new business models for their clients,’ said Jean-Pascal Bobst, CEO, BOBST Group. ‘At BOBST, our Industry Vision, based on four key pillars: connectivity, digitalisation, automation and sustainability, greatly supports this transformation. The new solutions are the latest in a line of continuous innovation to help our customers thrive in this new reality.’

At the heart of this vision is BOBST Connect, the company’s constantly evolving, cloud-based digital platform that enhances and improves packaging productivity. BOBST has announced the launch of Tool Management, which is something new and unique to the market. The Tool Management solution offers unprecedented control over TooLink equipped dies, integrating tool makers, tracking tool performance, feedback, maintenance, and orders. With an intuitive interface, it provides users with a multitude of data driven insights to bring tool management to the next level.

The Recipe Management for ACCUCHECK allows users to remotely prepare and set up an inspection recipe based on the artwork file, and to save recipes and retrieve parameters, anytime, anywhere, offering the beginning of the close loop solution. This feature is already being used successfully by BOBST customer Prealpi, helping them to improve set-up times and quality control.

BOBST has reinforced its automation and connectivity streams by acquiring 70% of the equity of Dücker Robotics, a world leader in the use of robots in both loading and palletising in the corrugated board sector, while offering opportunities in the folding carton industry. The company develops robotic systems for the most sophisticated converting machines.

Below are the other newly announced highlights from each industry sector.

Flexible Packaging

VISION K5 HS metalliser, to be launched later in June. The metallise gives high performance and high-speed metallising, and is designed to handle a variety of film types including heat sensitive, thin gauge and sustainable substrates. It includes the largest coating drum in the industry at 700mm. It is the ideal metallising solution available for converters.

NOVA MW LAMINATOR, to be launched at the end of July. It is a super compact laminating machine with an ergonomic and user-friendly design, perfect for solventless lamination of all narrow web applications within the flexible packaging market. Moreover, it is the ideal lamination solution for the growing digital print market.

VISION CI for paper applications, to be launched in Q4 2023. A flexo printing press serving the ever-growing market for paper, with further capability for diameter and higher web tension. The machine can run 120g of paper at 400m/minute and includes features such as BOBST’s Extended Colour Gamut (ECG) technology and SmartGPS to automate the start-up process.

Labels

Expanded Die-Cutting Portfolio: In addition to semi-rotary die-cutting, Quick Change rotary die-cutting has been introduced, which provides a 50% time saving to change magnetic cylinders.

In addition to the 370mm version, BOBST has introduced a 530mm high-performance semirotary die-cutter with automatic plate-change. Both modules include the Digi-Gap feature for even faster job changeovers.

DIGITAL MASTER series update: an enhancement package is coming soon, which includes new features, such as novelties for BOBST Connect, third party integration and new ACCUCHECK functionalities.

Pantone validation: BOBST digital printing technology has been officially Pantone validated. This means BOBST’s colour management engine (DFE) and print results are validated by Pantone, giving customers complete peace of mind.

New BOBST Sphere user interface (UI) for flexo and digital. This is a totally re-designed user interface, coming first to the DIGITAL MASTER series and in-line flexo M6, and then gradual implementation to other platforms.

Folding Carton

NOVAFOIL updates: Two new features have been added to the NOVAFOIL, the first inline foil stamping machine from BOBST to offer an advanced cross-foiling option. NOVAFOIL 106 with HOLOGRAM modules answers the demand for security packaging and brand protection onto the packaging of almost any product. OACS (Optimal Advance Computing System) calculates optimal foil advance – this feature is available both on the machine and now remotely too.

Digital Make Ready Tool: An exciting new tool that projects the original digital layout, helping to connect prepress with production. Best combined with the NOVAFOIL 106 and DIGITAL INSPECTION TABLE FC 106, it assures impeccable stamping register quality, reduces waste and minimises downtime.

New EXPERTFOLD, VISIONFOLD & NOVAFOLD: Earlier this year, BOBST renewed its folder-gluer portfolio for folding carton. The new generations come equipped with a host of new features with the objective to enhance the three folder-gluers, increase their productivity and move closer towards the BOBST Industry Vision of a fully digitalised and connected converting process with maximum automation and sustainability.

Corrugated Board

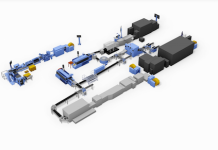

EXPERTFLEX: ideally suited to the production of e-commerce solutions and boxes for fast-moving consumer goods (FMCG). Combining the post-printing power with the die-cutting precision of the EXPERTCUT 1.7 I 2.1 flat-bed die cutter, it forms a single, highly automated EXPERTLINE packaging production line, a new, complete solution for high-quality printed and die-cut corrugated board.

SPEEDPACK updates: new strapping solutions will be introduced in July on this high-performing automatic packer, which delivers batches of boxes that are perfectly counted, stacked, banded and ready for palletisation. The new solutions increase its versatility, enabling the bundling of boxes with 5-15mm plastic straps commonly used in the corrugated board industry.

Services

BOBST’s new logistic hub for Europe, Middle East and Africa, situated in Belgium in the heart of Europe, with access to increased transportation solutions, is now up-and-running. One amazing feature of this new hub is the new Autostore, capable of managing up to 70,000 parts in a fully automated way.

BOBST Remote Assistance record numbers: BOBST continues to provide 24/7 remote support to its customers, including video and new augmented reality support, remote connection to machine and data analysis. Around 33,000 remote sessions are now conducted each year with dedicated Technical Support Specialists.

BESWICK MACHINERY – BOBST AUTHORISED AGENT SOUTHERN AFRICA

+27 11 433 2686

bmmarketing@beswick.co.za

www.beswick.co.za