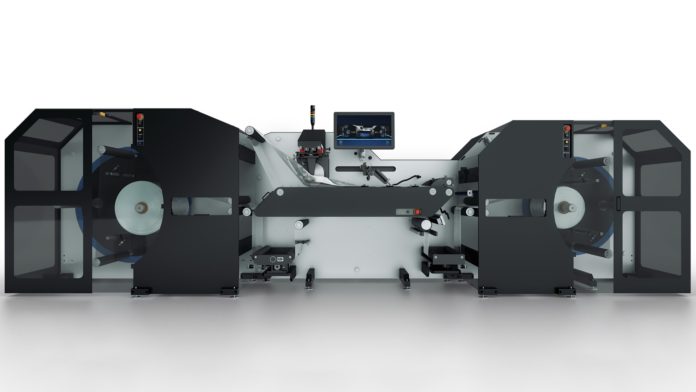

The Accraply Revolve machines leverage next-generation controls and an intuitive human-machine interface (HMI) to simplify operations. This new line of modular shrink sleeve seamers includes three machine configurations that were engineered to make shrink sleeve seaming simpler and more efficient.

Through the HMI, operators can access step-by-step help guides, diagnostic reporting, preventive maintenance alerts, on-board parts ordering and several additional resources. Also, advanced machine design features eliminate operator error.

‘One of the most exciting things about the Accraply Revolve line is how smoothly and easily the machines operate,’ said Joe Leonard, Accraply’s Converting Product Line Leader. ‘The technology and servo motors work together to create a crash-proof forming table that restricts operators from inputs that drive the machine out of spec, which limits operator dependency and dramatically reduces the risk of downtime.’

There are three machine configurations: the standard Accraply Revolve, the Accraply Revolve RT2 and the Accraply Revolve Fully Continuous. Each of these configurations has distinct, flexible options, with the intent to make it easier for customers to select the shrink sleeve seaming machine that is right for their business. The company will launch the Revolve line of seamers at Label Congress 2021, being held from 29-30 September in Chicago.

ACCRAPLY

https://www.accraply.com