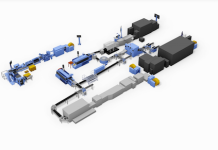

BOBST’s smartGRAVURE is a new tool that changes gravure printing from being a highly manual operation to a fully digitalised workflow. Aligned with Industry 5.0 principles and the pillars of BOBST’s vision for the future of packaging production, this innovation elevates the operator/machine interface while fully optimising the gravure process.

BOBST smartGRAVURE revolutionises the traditional gravure printing process by adding innovative elements of automation and digitalisation, while enhancing connectivity and sustainability. Encompassing both hardware and software, the solution has been developed to enable an easier and more productive way to print with gravure.

With automated colour management using BOBST oneECG (Extended Color Gamut), digitalised set up and controls, and connectivity with BOBST Connect, smartGRAVURE will increase productivity and output consistency, reduce downtime and complexity, and offer considerable sustainability benefits.

Delivering premium printing quality results, smartGRAVURE moves gravure printing to the next level as an end-to-end seamless process, no longer relying on the skills of the individual operator. This will secure the position and future of gravure, enabling printers to remain competitive in the packaging market.

For brand owners that require premium quality packaging, gravure has always been the obvious choice. However, until now, it has been a challenge for gravure printers to meet the increasing demands for shorter print runs, faster delivery and more sustainability.

By optimising the process with smartGRAVURE, printers can produce exceptional and consistent quality, with only a minimum waste of substrates and inks, and they can deliver the orders faster with high profitability, whether they are small, medium or long runs.

BESWICK MACHINERY – BOBST AUTHORISED AGENT SOUTHERN AFRICA

+27 11 433 2686

bmmarketing@beswick.co.za

www.beswick.co.za