Fujifilm’s 46kUV Inkjet Printbar System uses Fujifilm’s proprietary SAMBA® printhead technology, which leverages the precision of silicon MEMS (MicroElectrical Mechanical systems) processing and sputtered PZT (lead zirconate titanate) in a parallelogram shape. Additionally, Fujifilm’s 46kUV Inkjet Printer System has a native resolution of 1200 dots per inch (dpi) to cover a broad range of label quality needs, and can print individually unique QR codes, as well as produce high-quality small fonts.

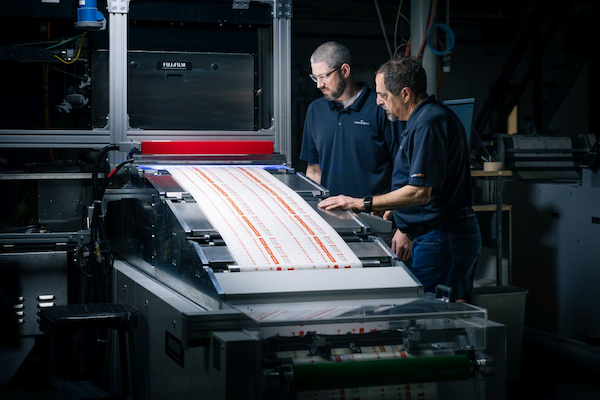

Concord Direct, a Concord, New Hampshire-based direct marketing agency for the non-profit industry, has provided its impressions of the newly installed Fujifilm 46kUV Inkjet Printbar System, an integrated printing solution for industrial production of labels and packaging launched by Fujifilm in December.

For more than six decades, Concord Direct has developed direct-response solutions for leading non-profits devoted to a wide cross-section of causes, including environmental, food relief, animal welfare, human services, and more. A turnkey production process, including extensive printing and the ability to meet deadlines, has long been critical to Concord’s success. Recently, the team saw the need to upgrade its printing system and chose the Fujifilm 46kUV Inkjet Printbar System.

‘We saw the need to look in a new direction for producing our work. After a visit to Fujifilm’s R&D facility for inkjet integration, we opted to partner with them,’ said Scott Hirsch, Plant Manager, Concord Direct.

‘Fujifilm has a long history in print, and the combination of Fujifilm’s technology and integration expertise was an added plus. The system is operator-friendly, efficient, and offers clean, smart software that has truly enhanced our operations.’

Installing Fujifilm’s 46kUV Inkjet Printbar System has resulted in a number of efficiency gains for Concord Direct. The 46kUV prints at speeds up to 152.4m (500 feet) per minute, a major improvement over Concord’s previous maximum printing speed of 91.4m (300 feet) per minute. Additionally, Concord was often restricted to running its old system at 194 feet per minute due to print quality, webbed material length in the machine, start-up time, and web tension challenges. The Fujifilm 46kUV Inkjet Printbar System, paired with the Fujifilm Transjet media transport, allows for easier access, quicker set up, and faster changeovers than Concord’s former system. According to Concord, their previous system also called for a significant amount of cleaning time, but with the Fujifilm system, the print stays crisp and clean and does not leave smudges or voids, which has reduced interruptions allowing them to maintain their production schedule more closely.

‘We’re honored that Concord Direct has selected Fujifilm’s integrated inkjet printing technology for the important work it does for so many meaningful non-profit organisations,’ said Greg Balch, vice president and general manager of the Fujifilm Integrated Inkjet Solutions group. ‘What we do best in the Fujifilm inkjet integration team is combine great technology with great support to create a sense of trust, and I’m so happy to see this come across in Concord Direct’s description of its experience.’

FUJIFILM SOUTH AFRICA

+27 11 430 5400

https://www.fujifilmgraphicsystems.co.za/