Across six inter-linked areas and two floors, Konica Minolta and MGI had over 30 live running machines, virtually the same number of software displays and demonstrated how the toner and inkjet technologies complement each other seamlessly in the print room of the future.

Konica Minolta’s and MGI’s joint drupa presence represented pioneering digital transformation across its 2400sqm booth at the exhibition in Düsseldorf, Germany, which ran until June 7.

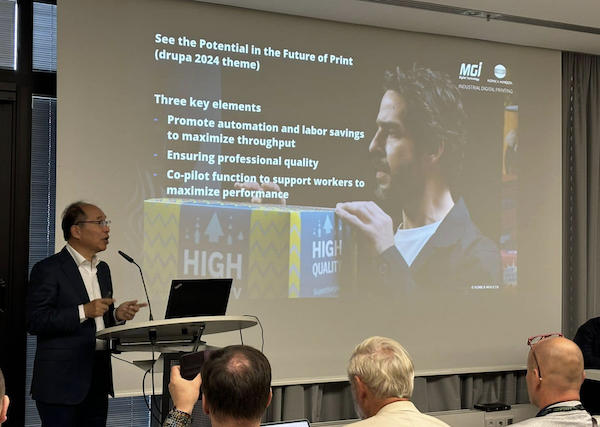

Konica Minolta had at least 20 European premieres at drupa where it has a strong focus on sustainability, the value of print and how customers can ‘See the Potential in the Future of Print’, its main messaging for drupa. It demonstrated ways of sustainable production in line with the philosophy of Industry 5.0. This is being achieved by assistance technology, labour-saving and easy-to-use operations improving the total throughput of all processes, not only printing.

At the heart of Konica Minolta’s demonstrations were unprecedented set-up configurations and new applications for Konica Minolta’s technology that have far-reaching implications for commercial printers and converters, as well as brand owners, designers and design and advertising agencies in the way they do business.

Among the 30 systems running live at drupa was Konica Minolta’s next generation HS-UV Inkjet Press, AccurioJet 60000, which was shown for the first time at drupa. This high-end model follows the quality and technology of the AccurioJet KM-1e series and has been further developed for maximising customer value and improving usability. The AccurioJet 60000 features an HS-UV Inkjet Press with a remarkable capacity of 6000 sheets per hour (sph) and offers both-side printing capabilities, ensuring versatility and efficiency in printing operations. This press was a highlight of the show and combines impressive speeds with excellent image quality. The use of Konica Minolta inline sensors and a spectrophotometer allows continuous monitoring and control of the printing process to ensure consistently high quality.

Another world debut at drupa was Konica Minolta’s AccurioPress C84hc press, which uses high chroma toner that prints bright and vivid colours consistently. It is the world’s only platform using the new toner, free of the restrictions imposed by the colour gamut of ordinary toners. Target customers include commercial printers, dedicated design houses, advertising agencies, corporates and brands.

Another example of Konica Minolta’s technology evolution involved partnering with MGI. Together they demonstrated how separate processes such as foiling, varnishing, printing, folding and drying can be combined into just one full integrated production run where MGI’s AlphaJet was centre stage and showing the benefits of a complete single-pass factory.

For customers, this will mean major savings in space requirements, power consumption and staff costs. Manual set-ups from different production engines will be combined into one completely automated system, including the use of software up to B1+ format size.

Multi-award-winning toner systems such as Konica Minolta’s AccurioPress C14000e toner press for high-volume production with more than 2200 global sales already, and the AccurioLabel 400, which is part of a single-pass portfolio that has already secured more than 1500 sales worldwide, were among the star performers at drupa.

New Products Unveiled At Drupa For The First Time Included:

PaperOne 5000

This belongs to an innovative range of SEI Laser systems which is the most technologically advanced for digital converting and finishing from SRA3 to B1 sheets for die-cutting and creasing in packaging and graphic arts. The B2 PaperOne 5000 modular system using Konica Minolta’s proprietary software Icaro can be used with one or multiple laser units and can be configurated according to customer requirements. Cutting, creasing and micro-perforation are some of the processes possible.

AccurioPro Colour Manager (APCM) Suite

New upgrades have been launched for this comprehensive colour management solution designed to streamline workflows with an integrated approach. AccurioPro Colour Manager includes seamless functionality with IQ-501, Konica Minolta’s own cutting-edge technology, or other external measurement devices.

AccurioPro Dashboard

This is an updated version of Konica Minolta’s advanced software tool covering the entire production workflow analysing complete processes. AccurioPro Dashboard captures the shop floor with great detail, enabling its users to reduce downtime as well as costs related to production. At the same time, the software helps maximise overall productivity by analysing the entire production process, automatically collecting and evaluating device information, and thus adding intelligence to print-related business decisions.

AccurioPro Flux

A raft of upgrades has been made to Konica Minolta’s AccurioPro Flux software solution, all designed to enhance workflow automation, expand business opportunities and enable greater flexibility for customers. Version 10 benefits all three modules: Essential, Premium and Ultimate, and the highlight is the refreshed and improved WebShop incorporating numerous new features. The latest iteration also offers greater support for Konica Minolta’s AccurioJet KM-1 press.

The AccurioPro Flux Label Impose option works seamlessly with Konica Minolta’s AccurioLabel presses and offers an all-in-one package for printing that allows print providers to import and impose artwork, manage print jobs, add variable data and print labels in one. Flux Label Impose also facilitates creating the correct data input for the creation of die tools, its VDP support, intuitive user interface and large print area of 320 x 480mm.

Omnia 100 is an auto feed die-cutting machine with a continuous sheet media loader and processing system with a high-capacity feeder from Valiani to attend the growing demand of personalised die-cutting processes, exclusive packaging without adding cost of dies and make-readies. It features full digital workflow integration, auto-setting and barcode or QR code reading, meaning no high skills are required by operators.

Additionally, new options for the MGI JetVarnish 3D Web 400 such as a JetSeal and an inline die-cutter, and MYIRO colour management tools for graphics arts applications, were shown. These included spectrophotometers for advanced colour management and for high-speed auto scanning.

The latest advances in areas such as Programmatic Printing with AI-generated content added to applications for totally targeted content were also demonstrated at drupa.

Unique software was shown at drupa, among them one premiere called ‘Ex Kansei’. The predictive software based on eye-tracking insights gathered from years of research can be used to turn invisible information into value by evaluating human elements such as attention, impression and positioning to analyse what the brain is thinking. Ex Kansei can analyse a wide range of brand assets, including product packaging, website advertising, direct mail, marketing materials, retail environments and in-store point of sale, as well as direct mail. Results are revealed within minutes of assets being uploaded to the cloud software, which quantitively analyses and visualises everything from the attention a product attracts and the impression it gives to the harmony of colours, the level of complexity, and its positioning.

Konica Minolta also showed how digital printing empowers printing on demand instead of ‘printing for the shelf’. An example of Konica Minolta’s ‘sustainability by default’ involved using recycled paper for all brochures and other marketing materials produced on-demand at drupa. Moreover, and for the first time, Konica Minolta did not take pre-printed materials to drupa. Instead, any of the Konica Minolta product sheets or other marketing materials could be ordered on a big display and were printed within seconds of any request on the automated lines running live.

Unique Robotics And Other Software Advances

Aiming to ignite printing possibilities, Konica Minolta showcased its vision of digital transformation in the print room of the future. A significant aspect of its demonstration revolved around the efficient use of digital equipment, specifically highlighting print automation.

Under the ‘mixed reality service’, Konica Minolta’s remote servicing operations were spotlighted where operators using headsets or smartphones with cameras can connect through the cloud to the Konica Minolta service desk to help with real-time remote visual support in the rare event of a problem.

Showcased at drupa, the smartphone app AIReLink is a specialised tool for service technicians developed by Konica Minolta based on years of experience with its 4000-plus technicians. Since it was launched, this has saved almost 10,000 customer visits, more than 300,000 kilometres of travel and reduced greenhouse gas emissions by 140 tonnes.

Combining modern order entry with automated processing, Konica Minolta has included two Cobots to hand over the printed brochures to the customer who ordered them.

At the show, the technology leader also worked with many partners to maximise the opportunities of its technologies. In addition to close cooperation with strategic partner MGI Digital Technology (MGI), other stand partners included Industrial Inkjet Ltd (IIJ), a specialist in bespoke inkjet customisation, and Plockmatic, a global supplier of finishing solutions that showed new products on the Konica Minolta stand. Valiani, an Italian producer of cutting machines and flatbed plotters, were present as well as SEI, a laser technology company. Also on the stand was MTEX NS from Portugal with their digital press for corrugated packaging production. Other partners like Fiery, Acco, Wirbelwild, Suchy, Upland, Grafisk Maskinfabrik (GM), Horizon and Kodak Creo as well as Konica Minolta internal divisions like Konica Minolta Sensing and FORXAI demonstrated their capabilities as well.

KONICA MINOLTA SOUTH AFRICA

+27 11 661 9000

https://www.konicaminoltasa.com/en-za