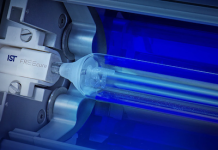

The MagiCoat™ Mini is a scaled iteration of the MagiCoat™ Pre-treatment System, and is equipped with state-of-the-art features in a compact footprint to meet the needs of those with lower production demands looking to pre-treat glass and other drinkware vessels for optimal adhesion.

The product allows users to pre-treat up to 10 items per minute; boasts a dedicated flaming station and an advanced flaming head; features four independently rotating stations, ensuring consistent quality; and uses a fine mist spraying system for even application.

The MagiCoat™ Mini hosts four independently rotating stations, one flaming station, a digital temperature control and one flaming head, working in conjunction with MagiCoat™ Solutions part A, B and C to promote adhesion on tapered and straight walled cylindrical vessels made of glass and other materials. Together, the MagiCoat™ Mini and MagiCoat™ Solution can achieve up to 200 residential washes or up to 600 industrial washes (wash testing results may vary depending on region).

With temperature detect, a key feature, the MagiCoat™ Mini automatically indexes upon reaching the optimal temperature to facilitate a uniform pre-treatment.

The MagiCoat™ Mini stands as the ultimate solution for businesses seeking to optimise their operations, offering streamlined pre-treatment processes for glassware and metallised-coated drinkware. With an outstanding capacity to pretreat up to 600 parts per hour, it facilitates production with ease. Additionally, it uses a water-based primer, MagiCoat™ Solution, that compiles with the stringent regulations of FDA 21 CFR 175.300, CPSIA, and California Prop 65.

INKCUPS

https://www.inkcups.com