UV equipment manufacturer IST METZ will present its product portfolio of UV and LED systems for label printing. The focus will be on the MBS®c, as well as the modulux LED systems.

Modulux specialises in no-frills, modular and robust systems for narrow web flexo printing applications. The LED systems are tailored to the market requirements of label printing. Whether upgrading or retrofitting: from the basic package to the all-inclusive variant, users can individualise the entire product as well as the optional service package without compromise and invest precisely.

The basic equipment of modulux systems consists of an LED unit, cooling, control cabinet and control system. The systems have an electrical conductivity of 90-100W/cm and a wavelength of 395nm. The concept of modulux allows users to configure the press individually according to their requirements. The basic equipment can be extended with additional IST technologies such as excimer, inerting or lamp systems. The LED systems are not only space and energy-saving, thanks to intelligent technologies, error analyses are also possible remotely.

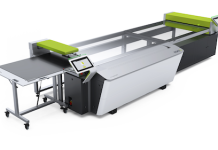

The air-cooled MBS®c is designed for mixed operation with LED-UV and is also prepared for a possible technology changeover to LED-UV. This means that the two different curing technologies can be easily combined on one machine. It is based on a modular system and can be used variably. With a high output of 200 W/cm, the compact and powerful UV unit is used wherever users have high curing requirements.

The MBSc has specially doped lamps with ballasts that are precisely matched to them. The URS® swivel reflectors used consist of so-called cold mirrors with more than 60 different metal oxide layers. The particularly resistant reflectors are characterised by very long service lives and optimum heat management. The URS® technology has a significantly higher reflectance than conventional reflectors. The inner housing of the MBS®c with lamp, reflector and swivel drive can simply be inserted into the outer housing. All supply connections can be plugged in automatically. The exhaust air volume and the air flow for cooling the unit have also been optimised to reduce contamination of the lamp and reflector. Machine downtimes can thus be reduced to a minimum.

The technology will be showcased at Labelexpo Europe, which will take place in Brussels from September 11-14. Also represented at Labelexpo will be sister company IST INTECH, specialising in high-performance LED systems for digital printing.

IST INTECH will present both water and air-cooled curing solutions for digital printing in the label sector. The UV and LED systems are available in both modular and custom designs. All common systems are equipped with the XT8 booster technology.

ATS – ADVANCED TECHNOLOGY SOLUTIONS (PTY) LTD.

+27 11 675 6397

enquiry@ist-uv.co.za

www.ist-uv.co.za