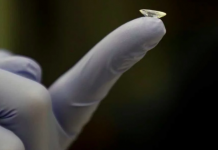

Nike Football has launched the Nike Vapor Laser Talon, the first-ever football cleat built using 3D printing technology. The Talon is designed to provide optimal traction on football turf and to help athletes maintain their drive stance longer.

Nike’s new 3D printed plate is contoured to allow football athletes to maintain their drive position longer and more efficiently, helping them accelerate faster through the critical first 10 yards of the 40, said Johnson. Translated to the game of football, mastering the Zero Step can mean the difference between a defensive lineman sacking the quarterback or getting blocked.

The plate of the cleat is crafted using Selective Laser Sintering technology (SLS). It is the sport’s first 3D-printed plate. SLS is a manufacturing technique that uses high-powered lasers to fuse small particles of materials into a three-dimentional shape. Through proprietary material selection, Nike was able to prototype a fully functional plate and traction system within a fraction of the traditional timeframe and at a fraction of the weight. The SLS process allows for the engineering and creation of shapes not possible in traditional manufacturing processes. It also provides the ability to make design updates within hours instead of months to truly accelerate the innovation process to never seen speeds.

SLS technology has revolutionised the way we design cleat plates – even beyond football – and gives Nike the ability to create solutions that were not possible within the constraints of traditional manufacturing processes, said Shane Kohatsu, Director of Nike Footwear Innovation.

Images and article source: http://nikeinc.com/