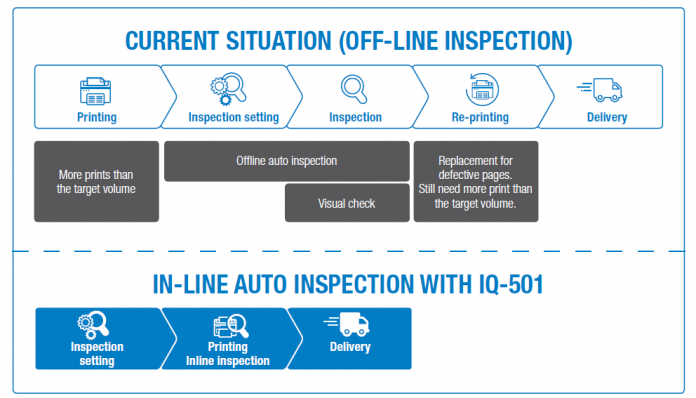

Auto Inspection Technology (AIT) is a new innovation by Konica Minolta South Africa and part of the company’s Intelligent Quality Care System, IQ-501. The technology automatically inspects every sheet of a print job, ensuring each individual page is delivered to the client’s requirements. The innovation is set to make a massive impact – boosting accuracy, efficiency and profitability for production-print clients.

‘Artificial Intelligence has sometimes been demonised in popular culture,’ said Edmund Jacobs, manager: commercial production print for Konica Minolta South Africa. ‘The reality is that AI can help us do our jobs better, quicker and more effectively, to provide a higher level of service.’

With AIT, manual inspection and intervention are something of the past, reducing misprints to an absolute minimum and making for more productive and more efficient print rooms. AIT is perfect for all print providers looking for easy, efficient and reliable print production.

Because of this greater accuracy, clients using the IQ-501 system will see fewer excess prints, reducing costs and generating higher margins. ‘Having an IQ-501 system managing your workflow makes for higher throughput, absolutely reliable production and the kind of time and waste savings that guarantee fast return on investment,’ said Jacobs.

The IQ -501 system offers clients:

• Highest reliability for all printed jobs.

• Shorter turnaround times with automated process.

• Ease of use, even for novice operators.

• Freed-up operator time for more important jobs.

• No surplus prints for estimated defects.

‘AIT is designed as a fully automated, closed-loop inspection technology to make sure your customers come back, not your printed products,’ said Jacobs.

KONICA MINOLTA SOUTH AFRICA (+27 11) 661 9000 http://www.kmsa.com