Heidelberger Druckmaschinen AGs (Heidelberg) drupa expectations were more than satisfied with almost 2000 orders from over 80 countries, including some 550 sheetfed offset presses.

The level of incoming orders during the show indicates that confidence within the industry in returning. The investment backlog is continuing to unwind in many parts of the world. We have received almost 2,000 orders from over 80 countries, including some 550 for sheetfed offset presses alone. The volume of orders at the show is therefore equivalent to around half of the production of printing units over the past financial year, said Bernhard Schreier, Heidelberg CEO.

Willingness to invest increases worldwide

All in all, drupa 2012 showed a greater willingness worldwide to invest in the print media industry. Alongside Germany, investment volumes in the Asian markets, in particular Japan and China, remained high or recorded significant growth. The other countries in this region also exhibited pleasing levels of investment in Heidelberg solutions. The emerging markets of South America, especially Brazil, also followed on from the incoming orders of recent quarters. Developments in the U.S. were also very satisfactory, with incoming orders ranking third among the individual markets. France, Russia, and the Middle East also recorded increases in order volumes.

Germany and China ranked first and second among the top markets, followed by the United States, the Middle East, the United Kingdom, and Japan.

Particularly the development in countries such as the U.S. and Japan fills us with optimism and exceeds our expectations. Many print shops have used drupa to thoroughly renew their machine park so as to be able to meet the requirements of the market, said Schreier.

Innovations drive investments

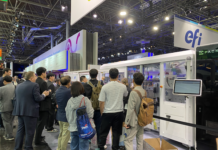

With some 60 innovations for the commercial and packaging printing sectors on show at drupa 2012, Heidelberg has underscored its position as the preferred solution provider in the print media industry and successfully positioned itself as market leader, innovator, and integrator for technologies and processes. Customers have preferably invested in solution packages across the entire Heidelberg portfolio. Over a third of all printing unit orders related to trade show innovations. The new Speedmaster SX machine platform presented at drupa fared particularly well, with almost 500 printing units being sold. The concept of transferring high-end technologies from the peak segment of the Speedmaster XL class to the proven machine platform of the Speedmaster SM class has hit the mark in meeting the markets needs. These technologies are now accessible to a broad range of users.

Trend towards greater productivity intensifies

The investments made by customers reaffirm the trend towards greater productivity and networking through software. The new flagship press in the 70x100cm format, the Speedmaster XL 106, turned out to be a bestseller and the most sold machine at the show. The long perfectors for commercial printing and models with UV technology for the growing packaging market were in particular demand. Customers from Germany, the United Kingdom, North America, and Japan were the primary investors in the cutting-edge technology of the Speedmaster XL 106. Heidelberg also concluded sizeable contracts for the large-format Speedmaster XL 145 and Speedmaster XL 162 presses, which proved particularly popular with customers in packaging printing and web-to-print companies. Its cutting-edge technology also convinced well-known customers previously with Heidelberg competitors to switch supplier.

The new Speedmaster XL 75 Anicolor, now kitted out with the Anicolour technology that has been so successful in the small format, was successfully launched and convinced many visitors.

High demand for postpress solutions

Heidelberg was also able to conclude numerous contracts for postpress products. The new Stitchmaster ST 500 saddle-stitcher, the enhanced Stahlfolder TH 82 folding machine, the Eurobind Pro adhesive binder and, in the packaging sector, the Varimatrix and Dymatrix die cutters and the Diana X 115 folding carton gluing machine were real crowd pullers at numerous customer demonstrations.

Customers convinced by the added value of the integrated digital printing portfolio

Many customers were also impressed with the digital printing presses that Heidelberg fully integrated into its portfolio at drupa 2012 under the name Linoprint. The ability to integrate the Linoprint C digital press for commercial printing into the print shop workflow – and thus the offset workflow – using the new Prinect Digital Print Manager was a pivotal factor in many customers investment decisions. As many Linoprint C presses were ordered at the show as had been bought throughout the entire 2011 calendar year.

Prinect firmly established as industry standard

Customers were particularly attracted by the functionality of Prinect, the operating system software for print shops, which is specifically tailored to the growth segments in the industry. All customer demonstrations were booked out from the first day of the show to the last. Proof that integration is undoubtedly the number one topic in the industry. Most of the demonstrations were devoted to the new Prinect Business Manager and Prinect Web-to-Print Manager. With over 100 integration solutions sold, Prinect can rightly claim to be the leading software in the industry.

Services and consumables go hand in hand with Heidelberg equipment solutions

Another highlight of the Heidelberg drupa stand was the very popular Services Area, where Heidelberg presented its portfolio of technical services, consumables, and performance services side by side with its equipment solutions. This made the added value of the portfolio even more apparent for many customers. The particular attractions included the range of Saphira ECO eco-friendly consumables that had been extended again for drupa, and the new service agreements specifically tailored to the needs of print shops different business models.

The eco-friendly aspect of the solutions presented was also covered in all the customer demonstrations. The spectrum ranged from the carbon-neutral stand itself and carbon offsetting of the entire press manufacturing process to green consumables and a portfolio of services geared towards lowering energy consumption in print shops. Heidelberg thus once again underlined its pioneering role in the field of ecological printing.

drupa has once again clearly demonstrated its importance as a major industry trade show. As for Heidelberg, our expectations of the trade show have been more than satisfied. The fact that we have remained true to our development projects over recent years, some of which have not been easy, has been rewarded. We can now also look to the future with optimism, said Schreier.