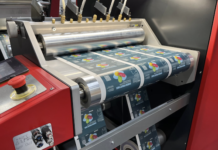

Image-based colour control, inspection capabilities, and now water control make QuadTech’s AccuCam™ the optimal automated system for newspaper printers. The company will introduce an enhanced version of its Color Control and Web Inspection System with AccuCam, adding automated, on-the-fly water control management at drupa. The new Water Control feature reduces the occurrence of common newspaper printing problems such as scumming and fan-out, by automatically adjusting ink and water levels.

Traditionally, maintaining the right balance of ink and plate dampening in offset printing has been a time-consuming, labour-intensive task. AccuCam’s high sensitivity to water-balance deviations ensures these actions are fulfilled at full press speed, freeing the press operator to use time more economically.

QuadTech Product Manager Greg Wuenstel said, QuadTech’s AccuCam with Water Control provides a single solution for ensuring reliable image-based colour control and water balance. This development will not only ensure optimum quality throughout the print run, but will also further reduce labour, and help printers realise ink savings.

Accurate ink and water balance is critical in order to prevent defects such as scumming, and to ensure optimal ink yields. Automating this process ensures consistency and eliminates the probability of human error, which can lead to overcompensation of ink or water settings and overuse of ink.

QuadTech’s Color Control and Web Inspection System with AccuCam™ is an automated, image-based, closed-loop colour control system that provides accuracy and consistency, detecting real-time defects across the entire printed web.

The AccuCam system utilises a proprietary 6-channel spectral sensor for CIELAB image-based color control. Analszing the entire image, AccuCam automatically compares the data to target aim point values from a high resolution prepress file, eliminating the need for colourbars or graybars. The system makes automatic ink key adjustments for consistent high colour quality and accuracy.