Goss International will exhibit new packaging capabilities at Labelexpo Europe, where it will present the latest offset technology developments and opportunities for converters.

Goss will highlight information about Alwan’s Color Expertise Technology, a recent addition to the Goss Sunday Vpak press series. This latest suite of software is now commercially available following months of rigorous testing at Goss’s Packaging Technology Centre, Durham, New Hampshire (USA).

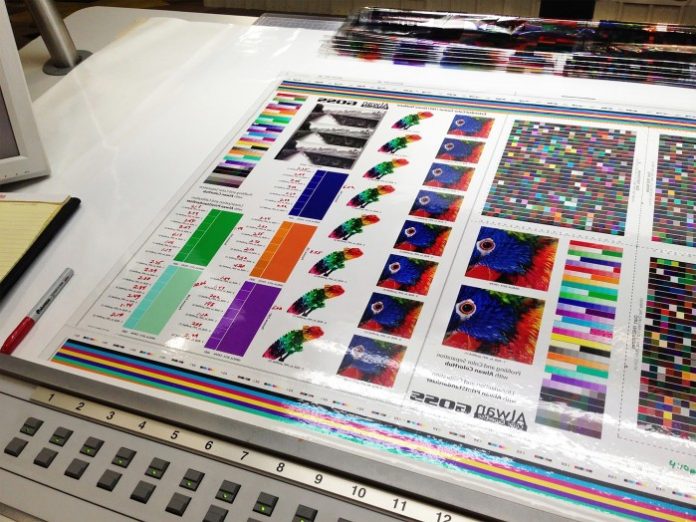

Alwan’s technology suite features an extended colour gamut, which adds two or three inks to conventional process inks, enabling exact brand colour reproduction without the need for spot inks. Facilitating a substantial reduction in the costs usually associated with ink changeovers, the update is expected to bring customers a 30 to 50 percent cost reduction compared to the use of spot inks through a combination of eliminating ink changeovers and reduced ink inventories.

David Muncaster, director of EMEA business development for packaging at Goss International said, ‘We are extremely committed to pushing the boundaries in printing and packaging, and consistently delivering best-in-class products. We are delighted to have partnered with Alwan, who share our passion for innovative print solutions. Our Vpak range already combines cost-effective hybrid solutions with superior print quality and the addition of Alwan’s extended colour gamut further strengthens our offering in the labels and packaging market. We are confident that our combined expertise will enable not only reduced time and material waste but will also allow us to continue delivering market-leading quality, flexibility and control.’

The extended colour gamut is just one feature on the four-part technology suite from Alwan that is now available on the full Goss product range. The suite also includes colour management and quality control software which helps to increase print quality and consistency; reduce cost and ultimately maximise productivity across the production cycle. Goss have also made a number of highly anticipated changes to its Vpak presses in order to further reduce waste and optimise the printing process for flexible packaging customers in particular.

According to Goss, the partnership and technology updates reflect the company’s commitment to driving ongoing development across their portfolio, and follow a number of recent ‘kaizen’ events held specifically to improve equipment design and streamline processes.

‘With the growing trend towards shorter run lengths, printers and converters are increasingly having to find solutions to balance customer expectations and profitability,’ continued Muncaster. ‘Our most recent ‘kaizen’ event focused on job changeover process which is now increasingly critical in order to make customers’ working lives easier and more profitable. We are extremely excited to share our latest developments at Labelexpo this year, and demonstrate how our people, products and partners are together delivering the flexibility, high quality and cost effectiveness that is so essential in today’s packaging market.’