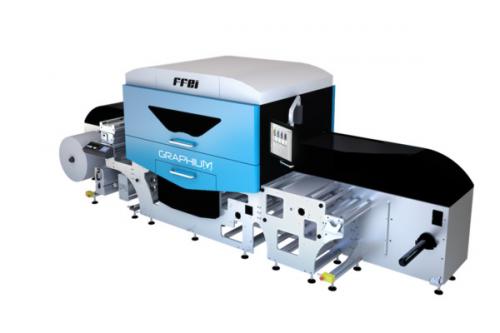

FFEI Ltd has launched Graphium, a digital UV inkjet press with high opacity digital white which can be used to produce labels, packaging and speciality print. Graphium will be unveiled at the upcoming Print13 in Chicago on the 8-12 September and the LabelExpo in Brussels on the 24-27 September.

Graphium enables a greater number of jobs to be converted digitally and allowing productivity, profitability and ability transformation for printers and converters to respond to dynamic product and market changes.

Andy Cook, FFEIs managing director, said that Graphium represents a new generation of digital inkjet press aimed at the narrow web market with a low capital investment, but a high quality print, unparalleled productivity and the most versatile range of applications.

This digital UV inkjet press combines a range of leading edge technologies that allow users to convert complex jobs that are not economically viable with standalone conventional or inkjet presses. The press converges innovative workflow, prepress, colour management software and cutting edge head calibration technology, ensuring consistent quality through repeatable production.

This guarantees a match between press and proof, aligning to colour standards. Printers and converters are able to benefit from high-quality, vibrant printing, with excellent adhesion, light fastness and durability.

Graphium uses specialist Uvijet Graphium UV curing inks developed by Fujifilm Speciality Ink Systems. These inks combine the functional performance, colour gamut and adhesion needed for label printing with reliable jetting performance required for consistent printing.

When developing this press, we wanted to bring our many years of software and inkjet expertise together to create a complete solution that transforms the print process. With Graphium, converters can now achieve greater efficiency from prepress to production and benefit from reduced start-up costs, minimal waste and increased productivity. The return on investment over conventional printing is huge – not only for short-runs, but longer also, said Cook.

This press offers convertors increased flexibility and productivity, enabling them to accept complex projects requiring a wide gamut of colours on virtually any substrate.

This inkjet press supports up to six digital modules and six flexo stations and offers the unique capability from a single vendor, of being able to integrate optional flexo and finishing stations inline for conversion in a single pass.